Ever looked at an image so vivid it felt like you could step right into it? The secret behind that stunning realism isn’t just brightness or sharpness—it’s the depth of the blacks. When the darkest parts of an image are truly black, every other colour pops with life. But when those blacks are a hazy, washed-out grey, the entire picture feels flat and lifeless.

This quest for “perfect black” is the holy grail of LED display technology. It’s the foundation upon which breathtaking visual experiences are built. But how do LED screens, which are made of tiny red, green and blue lights, manage to show an absence of light so perfectly? It’s not magic; it’s a fascinating science of controlling light at a microscopic level. Understanding this is the first step to appreciating what makes a truly great display.

What is Contrast Ratio, Really? (And Why It Matters More Than Brightness)

Before we dive into the technology, let’s clear up a fundamental concept: contrast ratio.

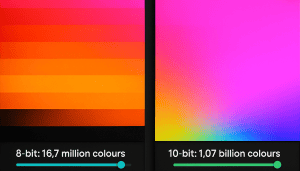

At its simplest, contrast ratio is the difference between the brightest white and the darkest black a screen can produce. A display with a 5,000:1 contrast ratio means its brightest white is 5,000 times brighter than its darkest black.

This single number is one of the most crucial indicators of picture quality. Why? Because a high contrast ratio means:

- Deeper, more convincing blacks.

- Brighter, punchier highlights.

- More detail visible in dark scenes.

- Richer, more saturated colours.

- Higher visibility in high levels of ambient brightness, for instance the image on a high contrast display that is in direct sunlight is far more visible that a lower contrast display even if they have the same level of brightness.

You may have seen displays advertised with astronomical “dynamic contrast ratios” in the millions. This can be misleading. Dynamic contrast is achieved by the display’s software dimming the backlight for dark scenes and brightening it for light ones. Native contrast, however, measures the panel’s inherent ability to display black and white simultaneously in a single image. It’s a far more honest and important measure of real-world performance. A screen with high native contrast will look fantastic all the time, not just in specific scenes.

This is why focusing solely on brightness is a common mistake. A screen can be incredibly bright, but if its black levels are poor (i.e., it produces grey instead of black), the image will look washed out. True visual impact comes from the difference between light and dark, which is defined by the fundamental display parameters.

The Technology Behind the Black: From SMD to GOB and COB

So, how do modern LED displays master the art of black? The answer lies in the evolution of how the tiny LED lights (diodes) are packaged and mounted.

The Traditional Way: Surface-Mounted Device (SMD)

For years, the industry standard has been SMD technology. This involves soldering individual red, green, and blue LED packages onto the surface of a printed circuit board (PCB).

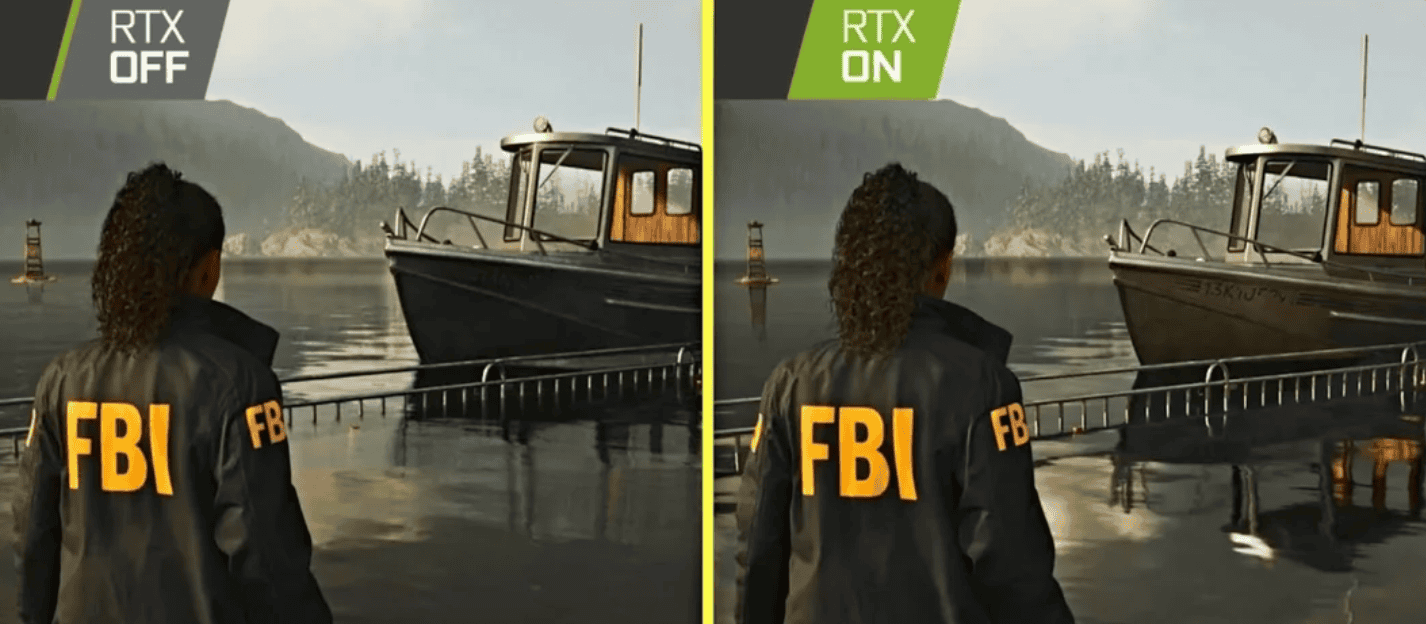

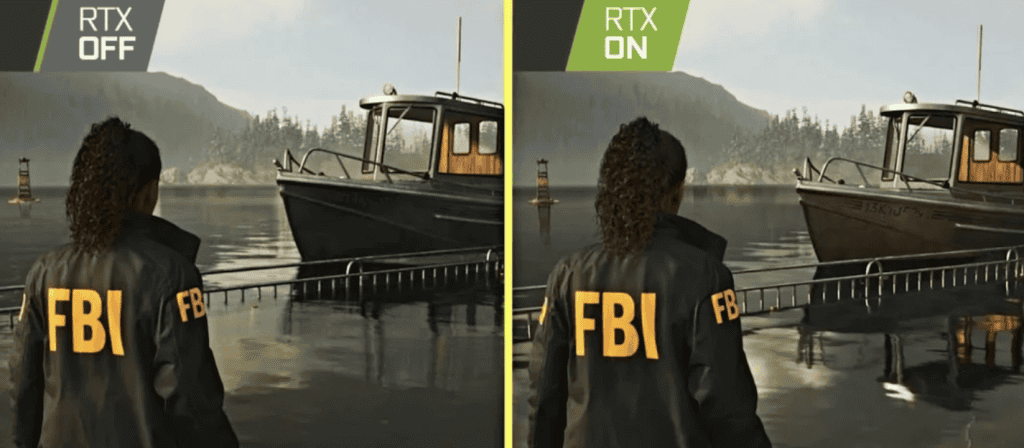

The Challenge with SMD: While effective, SMD has a built-in limitation for contrast. The individual diodes and the surrounding PCB surface can reflect ambient light, and light from one pixel can “bleed” or scatter, slightly illuminating its neighbours. This light pollution prevents the screen from achieving a truly deep, dark black, creating a slightly greyish floor instead.

The New Way: Encapsulation and On-Board Innovation

To solve the reflection and light bleed problem, engineers developed groundbreaking new approaches that fundamentally change the screen’s surface. The two leading innovations are Glue-on-Board (GOB) and Chip-on-Board (COB).

1. Glue-on-Board (GOB)

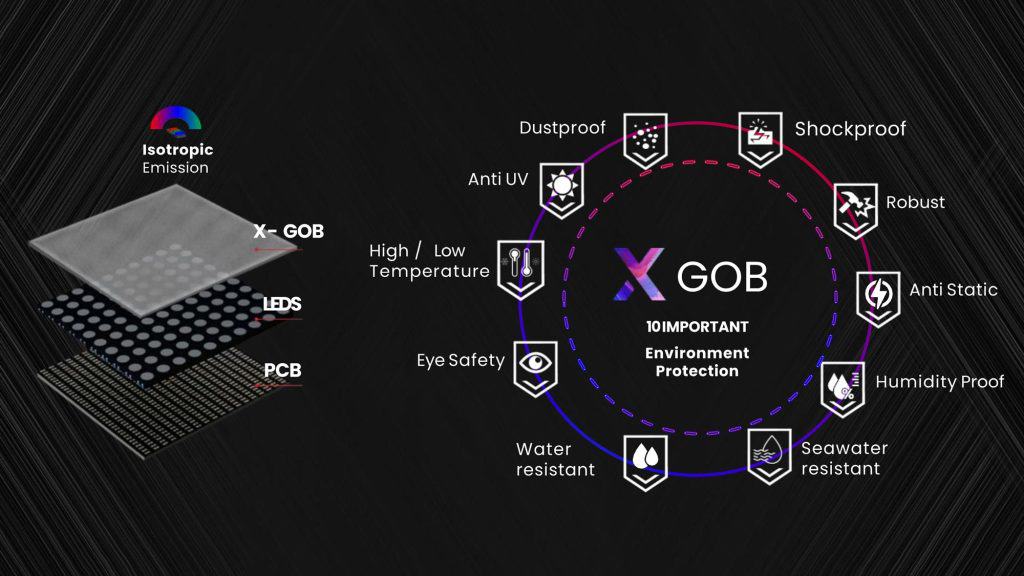

GOB is a clever enhancement of traditional SMD technology. After the SMD LEDs are mounted on the board, a specialised transparent epoxy resin is applied over the entire surface. This glue on board led technology does two critical things:

- Creates a Smooth, Non-Reflective Surface: The resin fills all the gaps between the LEDs, creating a single, flat plane that significantly reduces ambient light reflections.

- Enhances Durability: The hardened resin acts like a suit of armour, protecting the delicate LEDs from moisture, dust, and impact.

The result? A dramatic increase in contrast ratio (DRE Series reaches up to 6,000:1) and a much more robust display, all without having to completely reinvent the underlying manufacturing process.

2. Chip-on-Board (COB)

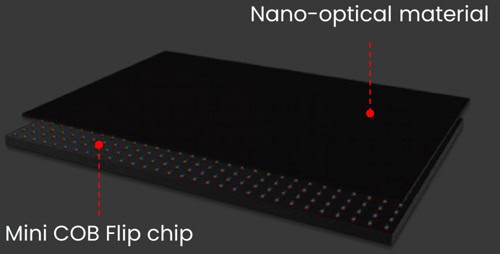

COB takes the concept a step further. Instead of packaging LEDs individually, COB technology mounts the tiny, bare LED chips directly onto the circuit board. The entire surface is then coated with a black, light-absorbing resin. Some advanced methods even use flip chip LED designs for even better thermal performance and reliability with contrast levels reaching up to 20,000:1 in the case of our DYF Series.

The Power of COB: This creates the ultimate black surface. There are no reflective metal legs or gaps between pixels. The screen itself is a deep, uniform black, allowing it to absorb almost all ambient light. The blackest parts of the image blend seamlessly with the physical screen, creating an unparalleled sense of depth and realism.

Head-to-Head: Choosing the Right Black for Your Needs

Each technology provides a distinct balance of performance, protection, and cost. Understanding these trade-offs is essential for selecting the appropriate LED display for a specific application.

- SMD (Surface-Mounted Device): The established standard. It’s cost-effective and suitable for applications where budget is a primary concern and ambient light can be controlled. However, it offers the lowest contrast and is the most fragile with LEDs often damaged, especially on the corners or sides of the LED cabinet.

- GOB (Glue-on-Board): The rugged all-rounder. It offers a huge leap in contrast and colour consistency over SMD, combined with excellent protection. This makes it ideal for high-traffic public areas, retail environments, and rental applications where durability is paramount, and it simplifies LED display maintenance.

- COB (Chip-on-Board): The ultimate performer. It delivers the highest possible contrast ratio and the deepest black levels, making it the top choice for applications where image quality is non-negotiable, such as broadcast studios, control rooms, and luxury home cinemas. These premium applications often demand creative led screens with flawless visual fidelity.

Frequently Asked Questions (FAQ)

What is “true black” in a display?

“True black” refers to a display’s ability to produce a deep, dark black that is indistinguishable from the screen being turned off. It’s achieved by minimising light emission and reflection from the display surface, which is the key to a high contrast ratio.

How do LED screens show black?

To show black, the individual red, green, and blue LEDs that make up a pixel are simply turned off. However, “true black” depends on how well the surrounding screen structure prevents reflections and light bleed from nearby active pixels. Technologies like COB and GOB excel at this and older SMD solutions sometimes adopt black face LEDs which also slightly improve the contrast compared to traditional white face LEDs.

Is a higher contrast ratio always better?

Yes, when referring to the native contrast ratio. A higher native contrast ratio directly translates to a more dynamic, vibrant, and detailed image with deeper blacks. Be wary of inflated “dynamic” contrast ratio figures, which are less indicative of real-world performance.

What is the main difference between COB, GOB, and SMD?

- SMD has individual, exposed LEDs soldered to a board. It’s the most basic and least contrasted.

- GOB covers SMD LEDs with a protective, contrast-enhancing resin. It’s durable and a huge visual step up.

- COB mounts bare LED chips directly onto a black board, creating a single, flat, ultra-black surface for the highest possible contrast.

Why should I care about deep contrast?

Deep contrast is the secret ingredient to visual immersion. It makes colours look richer, details in shadows become visible, and the overall image feels more three-dimensional and lifelike. Whether for a retail display that grabs attention or a broadcast studio that demands perfect colour, deep contrast is essential.

Beyond Black: The Future of Visuals

The journey from a hazy grey to a perfect black is a story of relentless innovation. By controlling light at the microscopic level, modern LED technology has unlocked a new level of visual fidelity. Understanding the science behind SMD, GOB, and COB empowers you to look beyond simple specs and recognise what truly makes a display exceptional.

When you’re ready to explore how different technologies are engineered for specific environments, from architectural installations to interactive floors, diving deeper into the world of bespoke LED solutions is your next step.