Ensuring Safe & Compliant LED Display Installations: A Practical Guide to Safety Standards

The vibrant glow of an LED display can transform a space, captivate an audience, and convey crucial information. From dynamic retail LED window displays to large-scale outdoor LED display screens, the visual impact is undeniable. However, behind every brilliant display lies a critical foundation: safe and compliant installation. Simply choosing a high-quality, certified LED display is only half the journey; ensuring it’s installed correctly, adhering to all relevant safety standards, is paramount for performance, longevity, and, most importantly, safety.

This guide delves into the essential aspects of compliance for LED display setup. We’ll explore why these standards are non-negotiable, decode key product certifications, and outline the practical safety considerations during the installation process. Understanding these elements empowers you to make informed decisions, ensuring your investment not only looks spectacular but also operates safely and reliably for years to come, offering true peace of mind.

Why Compliance and Safety Standards are Non-Negotiable

Adhering to rigorous compliance and safety standards during LED display board installation isn’t merely a box-ticking exercise; it’s fundamental to protecting your investment, your property, and the public. The risks associated with non-compliant installations are significant and far-reaching:

- Electrical Hazards: Improper wiring or the use of non-certified components can lead to electrical shocks, short circuits, and devastating fires. Compliance with standards like the National Electrical Code (NEC), particularly Articles 410 for luminaires and 600 for electric signs, is crucial.

- Structural Failures: LED displays, especially large outdoor LED display installations, can be heavy. Inadequate structural support, poor mounting techniques, or a failure to account for factors like wind load can result in catastrophic collapses, causing extensive damage and posing severe injury risks.

- Legal Penalties and Fines: Local authorities and regulatory bodies enforce strict codes. Non-compliance can lead to hefty fines, orders to remove the installation, and potential legal action.

- Voided Warranties: Manufacturers often stipulate that warranties are contingent upon proper installation according to their guidelines and relevant standards. A non-compliant setup could invalidate your warranty, leaving you to bear the cost of repairs or replacements.

- Reputational Damage: An unsafe or failing installation can severely damage your brand’s reputation, eroding customer trust and public confidence.

- Operational Downtime: Issues arising from poor installation can lead to display malfunctions, requiring costly downtime for repairs and disrupting business operations.

The core principle is clear: a certified LED display product, whether it’s an LED ticker display or a vast LED wall display, achieves its full safety and reliability potential only when coupled with a professional, compliant installation. The synergy between a quality product and expert installation is the bedrock of a successful and safe visual solution.

Decoding Essential Product Certifications for LED Displays

Understanding product certifications is the first step towards a safe installation. These marks indicate that a product has been independently tested and meets specific safety and performance standards. When planning your LED display setup, look for these key certifications:

A. Electrical Safety Certifications (e.g., UL, CE, ETL)

These certifications are paramount for any electronic device.

- What they mean: Marks like UL (Underwriters Laboratories), CE (Conformité Européenne – for the European Economic Area), and ETL (Intertek) signify that the LED display and its components (like power supplies) have undergone rigorous testing for electrical safety, including risks of fire and electric shock. For instance, UL-listed components are crucial for meeting safety requirements.

- Practical Implication: These certifications provide assurance that the components are designed and manufactured to prevent overheating, electrical faults, and related hazards during operation. This is especially important for compliance with electrical codes such as NEC Article 410 (luminaires) and 600 (electric signs).

- Reference: code-authorities.ul.com

B. Structural Integrity & Material Standards

The physical construction of the display and its mounting system are critical for safety.

- What they mean: While specific certifications vary, standards will address load-bearing capacity, resistance to environmental stresses (like wind-load ratings for outdoor LED displays), and the use of fire-retardant materials for enclosures and internal components. Materials are often rated by authorities like UL for their fire resistance.

- Practical Implication: Ensures the display can be securely mounted and will remain stable under expected conditions, preventing collapses or material failures that could lead to fires. Proper heat dissipation, influenced by material choice and design, is also a key safety factor.

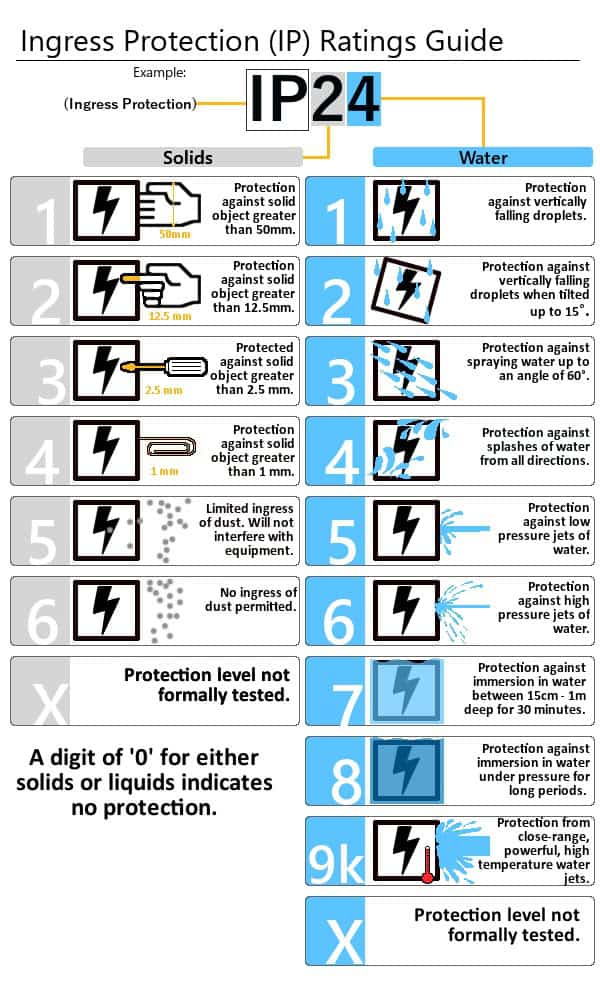

C. Environmental Protection (IP Ratings)

Particularly relevant for outdoor LED display installations or those in demanding indoor environments.

- What they mean: The Ingress Protection (IP) rating classifies the degree of protection provided by an enclosure against intrusion from solid objects (like dust) and liquids (like water). The first digit indicates solid particle protection, and the second indicates liquid ingress protection. For example, an IP65 rating signifies the display is “dust-tight” and protected against water jets from any direction – often a minimum for outdoor units.

- Practical Implication: A suitable IP rating ensures the display’s longevity and safe operation by preventing damage to internal electronics from environmental factors, reducing the risk of short circuits or corrosion.

D. Emission Standards (e.g., FCC)

These standards address the electromagnetic compatibility of the display.

- What they mean: Certifications like FCC (Federal Communications Commission) Part 15 in the USA regulate the amount of electromagnetic interference (EMI) or radio frequency interference (RFI) a device can emit.

- Practical Implication: Ensures your LED display screen, whether a mini LED display or a large video wall, doesn’t disrupt other nearby electronic devices, which is crucial in environments with sensitive equipment.

Choosing products with these certifications is a foundational step. However, their benefits are only fully realised when the installation itself adheres to best practices.

Key Safety Considerations During LED Display Setup

A compliant LED display setup involves meticulous planning, careful execution, and thorough verification. Here’s a breakdown of key safety considerations across the installation lifecycle:

A. Pre-Installation: Planning for Safety

Thorough preparation is non-negotiable for a safe and successful LED screen setup.

- Thorough Site Assessment: Evaluate the proposed location meticulously. This includes assessing the structural soundness of the mounting surface (building façade, ground, or custom structure) to ensure it can bear the display’s weight and any additional forces like wind. Accessibility for installation and future maintenance is also key.

- Understanding Local Regulations & Permits: Research and comply with all local zoning laws, building codes, and permit requirements. This can include restrictions on size, brightness, operating hours, and light pollution. Engaging with local authorities early can prevent costly delays or rework.

- Choosing the Right Certified Product for the Environment: Select an LED display with certifications and specifications (e.g., IP rating, wind load capacity) appropriate for its intended environment. An indoor LED display screen has different requirements than an outdoor LED display exposed to harsh weather.

B. During Installation: Adhering to Best Practices

The installation phase demands precision and adherence to safety protocols.

- Structural Mounting:

- Secure Frame Construction and Anchoring: Whether wall-mounted, freestanding, or suspended, the support structure must be engineered and installed to safely manage the display’s weight and any dynamic loads (e.g., wind). Follow design drawings meticulously.

- Weight Distribution and Load Management: Ensure even weight distribution across mounting points to prevent stress concentrations.

- Considerations for Different Mounting Types: Each method (wall, pole, hanging, LED display box integration) has unique structural and safety requirements.

- Electrical Installation:

- Safe Wiring Practices: All electrical work should ideally be performed by qualified and licensed electricians familiar with LED display systems and local codes (NEC, BS 7671 in the UK).

- Proper Grounding and Surge Protection: Essential for protecting the equipment from electrical faults and power surges, and for user safety.

- Power Supply Calculations and Management: Ensure power supplies are correctly sized, ventilated, and safely housed to prevent overheating.

- Worker Safety:

- Use of Personal Protective Equipment (PPE): Installers must use appropriate PPE, such as helmets, safety glasses, gloves, high-visibility clothing, and harnesses when working at height.

- Safe Lifting and Handling Techniques: LED panels and components can be heavy and awkward. Employ proper lifting equipment and techniques to prevent injuries and damage.

- Securing the Work Area: Cordon off the installation area with barriers and warning signs to protect workers and the public.

C. Post-Installation: Verification and Handover

Once the physical installation is complete, crucial checks ensure everything is operating safely and correctly.

- System Testing: Thoroughly test all aspects of the LED display, including image quality, brightness, colour uniformity, and control system functionality. Check for any hot spots on panels or power supplies.

- Checking for Secure Connections: Verify that all data and power cables are securely connected and properly managed to prevent accidental disconnection or damage.

- Documentation of the Installation Process: Maintain comprehensive records of the installation, including design plans, component lists, compliance checks, and photographs. This is vital for future maintenance, troubleshooting, and demonstrating due diligence.

The Role of Professional Installation Services

While understanding these standards is beneficial, the complexity of modern LED display installations, from LED sphere displays to intricate flexible LED screens, often necessitates professional expertise. Hiring experienced and certified installers, like the teams at Dynamo LED Displays, offers significant advantages:

- Expertise in Navigating Regulations and Certifications: Professionals are well-versed in the myriad of local and international standards (CE, ROHS, FCC, etc.) and can ensure your installation meets all legal requirements.

- Ensuring Adherence to All Safety Standards: Trained installers understand the nuances of structural engineering, electrical safety, and worksite safety, minimising risks during and after setup.

- Proper Tools and Techniques: Professional teams have the specialised equipment and know-how for a secure, efficient, and aesthetically pleasing installation, whether it’s a giant outdoor LED display or a delicate transparent LED screen.

- Troubleshooting and Long-Term Support: Experienced installers can quickly diagnose and resolve any issues that may arise and often provide ongoing maintenance advice or services to ensure the longevity and optimal performance of your display.

- Maximising Product Value: Professional installation ensures that your high-quality, certified LED product is installed according to manufacturer specifications and safety guidelines. This not only guarantees optimal performance but also upholds warranty conditions.

Choosing a professional installation service extends the value of your investment in certified LED technology by ensuring it is implemented correctly, safely, and compliantly from day one.

Conclusion: Safety and Compliance as an Investment

The journey to a stunning and effective LED display doesn’t end with product selection; it culminates in a safe, compliant, and meticulously executed installation. Adhering to safety standards and understanding the importance of product certifications like CE, UL, and IP ratings are not just regulatory hurdles but crucial investments in the reliability, longevity, and safety of your system.

From initial site assessment for an outdoor LED display to the final checks on an indoor LED display board, every step must prioritise safety and compliance. This approach not only mitigates risks of electrical hazards or structural failures but also protects your reputation and ensures peace of mind.

For expert assistance in ensuring your LED display installation is safe, compliant, and performs to its highest potential, consider consulting with professionals who have a proven track record in designing, manufacturing, and installing high-quality LED solutions.

Further Reading

For more detailed information on specific standards and best practices, the following resource may be helpful:

- UL Code Authorities: LED Signs and Luminaires: Navigating the Standards and Codes (code-authorities.ul.com)