LED Production and Factory Solutions

Whether you are trying to relay information to your employees or to your customers, it is common sense that the better informed you are able to keep them, the better the results you reap are going to be.

LED production counter displays are arguably one of the best platforms for relaying information to a large group of employees. Before LED factories and production signs were an option, what were you doing to get information to your employees? Most factories use emails, brochures, memos, and postings to relay information. Using moving signs and/or factory signs to relay LED information is going to get you more results because it will grab the attention of your employees.

Statistics show that factories that install an LED production display and LED countersign into their facility have a workforce that is consistently more productive than those without one. The key to using LED factory signs to promote productivity is about what LED information you put on these signs. For example, having an LED production counter display gives your employees insight into that how well they are doing and how much work they are getting done. Statistics show that your employees are going to work harder, faster, and longer thanks to this LED production display because it will boost their morale. Even displaying information on your LED sign that spotlights the most productive employees will boost morale. It is going to make those that were highlighted feel good about themselves, and it is going to make everyone else want to work harder to get their name up in lights.

Dynamo LED Production Counter Displays and Data Analytics

Part of a worldwide manufacturing group, Sanoh Uk based Bristol manufacture brake and injector pipe assemblies for car manufacturers including Jaguar Landrover. As part of their philosophy of continuous improvement during the manufacturing process, they approached Dynamo LED Displays to provide a system capable of monitoring and displaying the current production state on eight of their manufacturing lines.

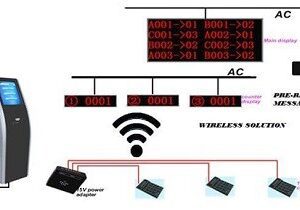

Dynamo designed and manufactured a floor-mounted display fixture for each of the eight lines that also included a data acquisition module to monitor the closed contact count output from the PLC running the line. Each display fixture shows the target and actual values required for the shift as well as the efficiency achieved. To make installation and any layout changes on the factory floor easier, each display fixture is linked to the main control server through a wifi network installed by Dynamo. To allow centralized monitoring from the shop floor, Dynamo provided a double-sided display measuring 5M wide by 1M high that was suspended from the factory roof. This display shows the Target, Actual and efficiency values for the current shift as well as the actual production figure achieved by the previous shift. In addition, a ticker display is included at the bottom of the display for any information that needs to be conveyed to employees or visitors. The software provided by Dynamo allows managers to configure shift times, set target figures for the shifts, and monitor in real-time the actual production status of all lines, without having to go to the shop floor. As a demonstration of the effectiveness of the system, within minutes of its installation, a production issue was spotted on one of the lines.