COB, GOB, and SMD LED Technology are currently the most common types used in the industry. Choosing the right fine pixel pitch LED technology is one of the most critical decisions you’ll make for your digital display project. With the market projected to exceed £4.5 billion by 2030, the technology is advancing rapidly, but so is the complexity. You’re not just buying a screen; you’re investing in a visual centrepiece that needs to perform flawlessly for years.

Get this decision wrong, and you risk poor image quality, unexpected maintenance costs, and a shorter-than-expected lifespan. Get it right, and you create an unforgettable visual experience that delivers a powerful return on investment.

This guide moves beyond generic definitions. We’ll provide a transparent, practical comparison of the three leading technologies—SMD, GOB, and COB—so you can confidently select the perfect solution for your specific application.

The Contenders: What Are SMD, GOB & COB?

Before we compare them, let’s establish a clear understanding of each technology. Think of it like this:

- SMD (Surface-Mounted Device): This is the traditional workhorse of the LED world. Individual red, green, and blue diodes are packaged together into a tiny component, which is then soldered onto a circuit board (PCB). It’s the established, modular standard.

- GOB (Glue-on-Board): This is an evolution of SMD. It takes a standard SMD module and applies a transparent layer of specialised epoxy glue across the entire surface. This creates a protective shield over the delicate LED components. You can learn more about this process in our deep dive on glue on board led technology.

- COB (Chip-on-Board): This represents a fundamental shift in manufacturing. Instead of packaging diodes first, COB technology mounts the raw, unpackaged LED chips directly onto the circuit board. The entire surface is then coated with a protective resin.

Each approach has significant implications for durability, visual performance, and cost.

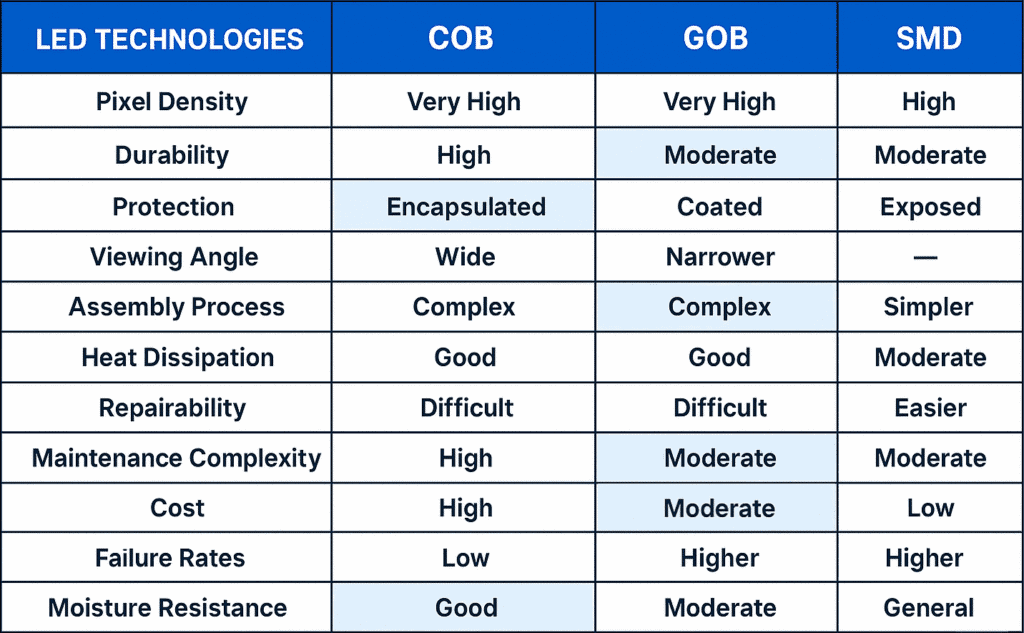

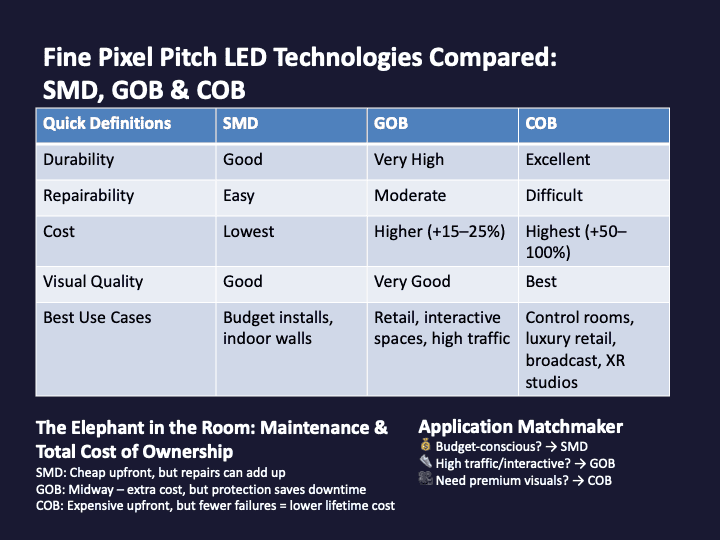

The Ultimate Comparison Matrix

For those who need a quick, high-level overview, this table breaks down the key differences between SMD, GOB, and COB technologies.

Now, let’s explore each technology in greater detail.

Deep Dive 1: SMD — The Proven Workhorse

SMD technology has been the industry standard for years, offering a mature and cost-effective solution for a wide range of LED display screen applications.

Advantages of SMD

- Cost-Effectiveness: As the most established manufacturing process, SMD benefits from economies of scale, making it the most budget-friendly option, especially at larger pixel pitches.

- Mature Technology: The technology is well-understood, reliable, and offers excellent colour uniformity and consistency across batches.

- Ease of Maintenance: Individual pixels or modules can be repaired or replaced on-site with relative ease, simplifying led screen maintenance.

Disadvantages of SMD

- Vulnerability: The exposed solder points and LED components are susceptible to damage from impact, dust, and moisture, leading to pixel failure if not handled carefully.

- Lower Contrast: The black PCB surface is broken up by the reflective metal solder points, which can slightly reduce the overall black level and contrast ratio.

- “Dead Pixel” Effect: When a pixel fails, it can be quite noticeable, creating a distracting black spot on the screen.

Deep Dive 2: GOB — The Rugged Protector

GOB was developed to address the primary weakness of SMD: its fragility. By adding a protective coating, it creates a far more resilient surface suitable for high-traffic or demanding environments.

Advantages of GOB

- Superior Durability: The epoxy layer provides excellent protection against impact, moisture, dust, and static electricity. This makes it ideal for interactive floors, rental screens, and retail installations where the public might touch the screen.

- Easier Cleaning: The smooth, sealed surface can be wiped clean without fear of damaging the underlying electronics.

- Enhanced Contrast: The glue can create a darker, more uniform surface, which improves the black levels and overall contrast ratio compared to standard SMD.

Disadvantages of GOB

- Repair Complexity: While more durable, if a pixel does fail underneath the glue, repair is more complex. The entire module often needs to be replaced, as isolating a single pixel is difficult.

- Heat Dissipation: The additional layer of glue can slightly impede heat dissipation, which must be managed with quality cabinet design.

- Potential for Yellowing: Lower-quality epoxy can yellow over time when exposed to UV light, affecting colour purity. Sourcing from a reputable manufacturer like Dynamo is crucial to avoid this.

Deep Dive 3: COB — The Premium Performer

COB represents the cutting edge of fine pixel pitch displays. By bonding chips directly to the board, it creates a truly seamless and robust surface with unparalleled visual performance.

Advantages of COB

- Exceptional Durability: With no exposed soldering and a solid resin surface, COB is highly resistant to impact and environmental factors. It offers the highest level of protection.

- Superior Visuals: The technology allows for much finer pixel pitches and produces a perfectly uniform, deep black surface, resulting in cinematic contrast ratios and incredibly smooth images. Viewing angles are also wider.

- Better Heat Management: Mounting the chip directly to the PCB creates a more efficient path for heat to dissipate, improving reliability and potentially extending the screen’s lifespan.

Disadvantages of COB

- Higher Cost: The manufacturing process for COB is more complex and has a lower yield, making it the most expensive option upfront.

- Colour Consistency Challenges: Achieving perfect colour uniformity across different production batches can be difficult, making it vital to source your entire display from a single, high-quality batch.

- Complex Repairs: Like GOB, on-site pixel repair is not feasible. Damaged modules must be returned to the factory for specialised repair, meaning module-level replacement is the standard service approach.

The Elephant in the Room: Durability, Failure Rates & Maintenance

A screen’s specification sheet only tells half the story. The real-world performance, reliability, and total cost of ownership are what truly matter. This is where a transparent discussion of failure modes becomes essential.

- SMD Failure: The most common failure is a “dead pixel” caused by physical impact or a broken solder joint. While fixable, high traffic areas can see this become a recurring issue.

- GOB Failure: Failures are rare and almost always due to internal component issues rather than external factors. However, a failure means a full module replacement, which can be more costly than a single SMD pixel fix.

- COB Failure: COB has the lowest failure rate due to its robust design. Like GOB, any failures require module replacement, but the likelihood is significantly lower.

When considering total cost of ownership, you must balance the upfront investment against long-term reliability. A more durable technology like GOB or COB may have a higher initial price but can lead to lower maintenance costs and less downtime over its life, a key factor in LED screen degradation over time.

Application Matchmaker: Which Tech is Right for Your Project?

The best technology is the one that fits your specific needs and environment. Use this guide to determine which solution aligns with your project goals.

Choose SMD If…

- Your budget is the primary constraint.

- The screen is installed in a low-traffic area, away from public reach (e.g., high on a wall or in a secure broadcast studio).

- You prioritise ease of on-site repair for individual pixels.

- Ideal Use Cases: High-level digital signage, retail windows, command centres where the screen is not subject to physical contact.

Choose GOB If…

- The display is in a high-traffic public space like a retail store, museum, or corporate lobby.

- Durability and protection from impact or moisture are key requirements.

- You need a balance between robustness and cost. Our DRE Series is a perfect example of a GOB-protected product designed for architectural and rental use.

- Ideal Use Cases: Interactive floors, retail shopfronts, rental and staging for events, public transport hubs.

Choose COB If…

- Your priority is the absolute best visual quality, with superior contrast and seamless images.

- The application demands ultra-high resolution and very fine pixel pitches (below P1.2).

- The screen will be viewed from a very close distance, such as in a premium boardroom or home cinema.

- Ideal Use Cases: Luxury corporate boardrooms, high-end retail showrooms, virtual production studios, control rooms requiring flawless detail.

Frequently Asked Questions

Q: Is COB technology going to make SMD and GOB obsolete?

Not necessarily. While COB offers superior performance, its higher cost means SMD and GOB remain excellent, practical choices for many applications. SMD is a cost-effective solution for mass digital signage, and GOB provides a crucial durability upgrade that is perfect for most public spaces. The choice depends on balancing performance needs with budget realities, and our buying guide can help you weigh these factors.

Q: How much more expensive is COB compared to GOB and SMD?

The cost difference can be significant, but it’s narrowing. Generally, for a similar pixel pitch, GOB might carry a 15-25% premium over SMD. COB can be 50-100% more expensive than GOB, especially at very fine pixel pitches. However, this is a generalisation; pricing depends heavily on the specific display parameters, resolution, and manufacturer. The key is to evaluate the total cost of ownership, not just the upfront price.

Q: Can you see a difference in visual quality between the three with the naked eye?

Yes, especially up close. When viewing a COB led video wall, you’ll notice a deeper, more uniform black background and a smoother, more film-like image. The difference between SMD and GOB is less about baseline image quality and more about ruggedness, though GOB’s coating can enhance contrast slightly. The most significant visual leap is from SMD/GOB to COB.

Q: Does the epoxy layer in GOB yellow over time?

Yes, but only on the cheap and low quality GOB solutions. Some solutions such as the ones sold by Dynamo do not suffer from yellowing and their colour is uniform across all of the LED modules. But there are certainly cheaper versions that will yellow over time, just be sure to only buy from a reputable company and you should be fine.

Q: Can COB & GOB displays be serviced onsite easily?

Yes, at least in the same way that all other LED displays can be serviced. The only thing that is different to traditional LED screen servicing is the actual LED module which is difficult to service on site as it’s tricky removing the resin to service LEDs and chips. So the power supplies, receiver cards and everything else can be serviced as normal just not the LED module.

Q: What happens with heat in GOB systems?

Sometimes GOB modules will get warm spots on the modules will affect the visual output on that part of the screen. It’s pretty rare and not something you’ll see with the high end GOB solutions. Novastar has a setting called adaptive thermal compensation built into its system that actually helps with this issue.

Making Your Decision

Choosing the right LED technology is a strategic decision that impacts your budget, operations, and the visual experience you deliver.

- For cost-effective, proven performance in protected environments, SMD is a reliable choice.

- For durable, high-traffic applications where reliability is paramount, GOB offers the perfect blend of protection and value.

- For ultimate visual fidelity and robustness in premium settings, COB is the clear winner.

At Dynamo LED Displays, we specialise in engineering bespoke solutions tailored to your unique environment and objectives. We don’t just sell screens; we partner with you to design, manufacture, and install the ideal display technology for your project, from the rugged DRE Series with GOB protection to custom-built COB installations.

If you’re ready to discuss your project with an expert who can provide a recommendation based on your specific needs, contact our team today for a no-obligation consultation.