If you’re evaluating LED display technology, you’ve likely encountered a flood of acronyms: SMD, IMD, COB, and now, MIP. It’s easy to get lost in the technical jargon, but the core challenge is simple: choosing a technology that delivers on its promises not just on day one, but for years to come. You need a display that’s durable, efficient, visually stunning, and financially sound over its entire lifecycle.

This is where Micro LED-in-Package (MIP) enters the conversation. It’s not just another option; it’s a strategic advancement designed to solve the very real limitations of previous technologies.

This guide is for the decision-makers—the technical buyers, systems integrators, and creative directors who need to look beyond spec sheets. We’ll cut through the noise and provide an honest assessment of how MIP stacks up against the alternatives, where it delivers the most value today, and what its evolution means for your next project.

MIP Demystified: The Core Technology Behind Micro LED-in-Package

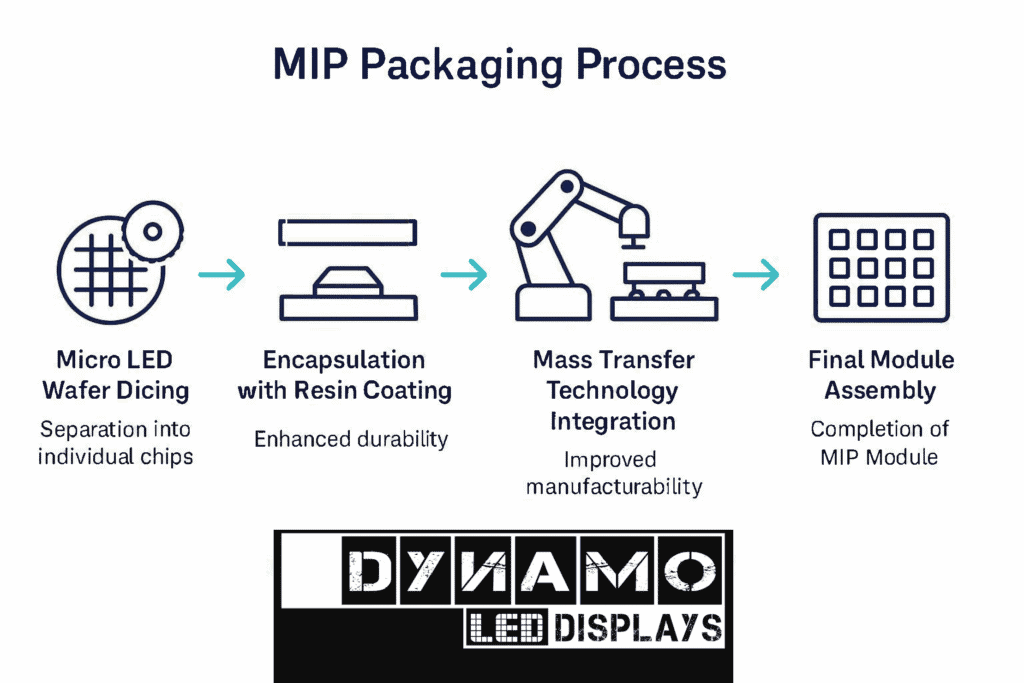

At its heart, MIP is a smarter way to build an LED display. Instead of placing tiny, fragile LED chips directly onto a large circuit board (like COB) or using larger, traditional packages (like SMD), MIP takes a hybrid approach.

It starts by packaging microscopic LED chips (MicroLEDs) into a tiny, robust capsule first. These encapsulated pixels are then mounted onto the final display module using the same high-speed, reliable equipment used for SMD production for years. This seemingly small change has massive implications for performance, manufacturability, and cost. It effectively combines the scalability of SMD manufacturing with the visual potential of MicroLEDs, solving critical production hurdles like mass transfer yield that have challenged other technologies.

The Great Display Debate: MIP vs. SMD, IMD, and COB – A Comprehensive Technical Comparison

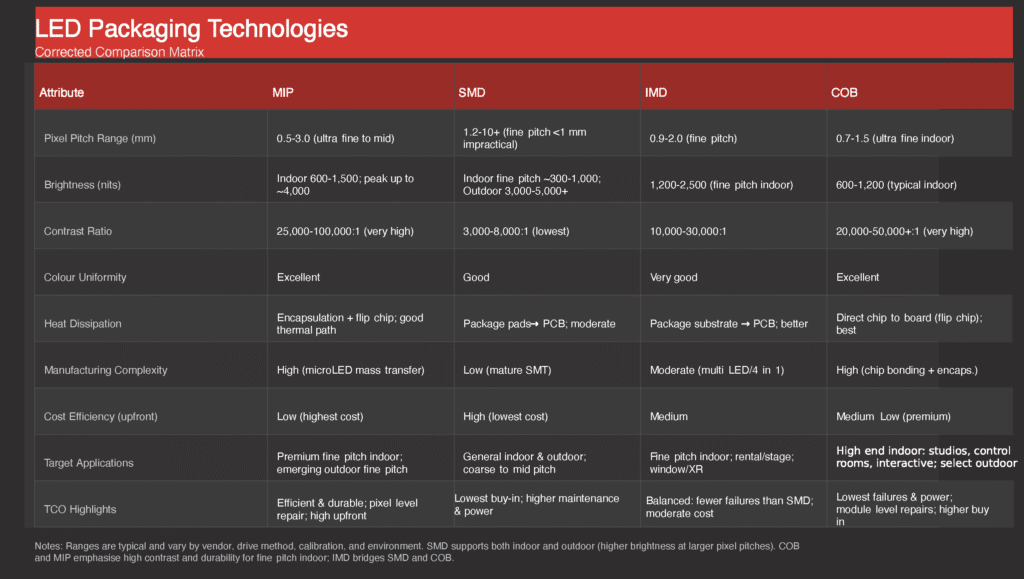

Choosing the right packaging technology depends entirely on your application’s demands for pixel pitch, durability, and total cost of ownership. While SMD remains a workhorse for larger pitch displays and COB offers excellent fine-pitch visuals, MIP is engineered to provide a superior balance across nearly every critical metric.

What are Key Differentiators to Consider?

Visual Performance

While COB is known for its smooth surface and excellent contrast, MIP matches this performance and often exceeds it in brightness and colour consistency.

Because each MicroLED in an MIP package can be individually tested and sorted before being placed on the final module, colour uniformity across the entire display is exceptionally high from the start.

This pre-testing process, known as “binning,” is much more difficult and costly with COB, where a single bad chip can compromise an entire section of a module.

Durability and Reliability

This is where MIP creates significant separation. Traditional SMD components are notoriously fragile, susceptible to damage from even minor impacts.

COB improves this with a surface coating, but MIP takes it further. The encapsulation of each individual pixel makes it fundamentally more robust.

Industry analysis shows MIP displays can be up to five times more resistant to physical impacts, moisture, and static than their SMD counterparts, a critical factor for public-facing displays or high-traffic environments.

The Repairability Conundrum: A Definitive Answer

You may find conflicting information online about whether MIP is repairable.

Let’s clarify: MIP displays are designed for on-site, individual pixel repair. This is a major advantage over most COB displays, where a single pixel failure often requires replacing an entire module—a costly and time-consuming process that can also lead to colour matching issues with older modules.

MIP’s serviceability significantly lowers long-term maintenance costs and maximises uptime.

Manufacturing and Cost Efficiency

Here lies MIP’s strategic genius. By leveraging existing, mature SMT (Surface-Mount Technology) assembly lines, manufacturers can produce MIP displays without the massive capital investment required for COB.

This efficiency translates directly to the end user. Studies suggest MIP can slash production costs by 25-30% versus COB while delivering comparable or superior quality.

This makes ultra-fine pixel pitch displays more accessible than ever before.

Real-World Impact: Where MIP LED Displays Excel Today and Tomorrow

Theory is one thing; application is everything. MIP isn’t just a technical achievement—it’s a problem-solver for the most demanding visual environments.

XR Stages & Virtual Production

For virtual production, reality is the benchmark. MIP delivers the ultra-fine pixel pitches (down to 0.4mm) needed to eliminate moiré and create seamless, camera-ready backgrounds.

Its high brightness cuts through harsh studio lighting, and enhanced colour gamuts, often boosted with Quantum Dot technology, produce the lifelike colours that sell the illusion. The durability also means less worry about accidental damage on a busy set.

Digital Out-of-Home (DOOH)

In the competitive world of DOOH, uptime and visual impact are paramount. MIP’s superior durability and resistance to weather make it a perfect fit for high-stakes outdoor digital signage.

With brightness levels capable of reaching 4,000 nits or more and ultra high levels of contrast, content remains vibrant even in direct sunlight. And because it offers significant energy savings—up to 40% compared to legacy SMD—the operational cost for large-format, 24/7 displays is substantially lower.

Control Rooms & Mission-Critical Environments

Clarity and reliability are non-negotiable in a command center. MIP provides the high resolution needed to monitor complex data streams without pixelation.

Its exceptional reliability ensures 24/7 operation, while its efficient heat dissipation reduces the strain on cooling systems. Most importantly, the ability to perform quick, on-site repairs minimises downtime when every second counts.

Retail & Luxury Displays

To capture consumer attention, brands need displays that are both breathtaking and practical.

MIP’s deep contrast ratios (often exceeding 25,000:1) make products pop with incredible depth and vibrancy. The technology’s robust nature is ideal for interactive installations or high-traffic areas.

For brands focused on sustainability, the lower power consumption of MIP aligns perfectly with corporate green initiatives, enhancing the story behind our custom LED installations.

MIP’s Horizon: Powering the Future of Displays

The MicroLED display market is projected for explosive growth, and MIP is a key catalyst. As the technology matures, you can expect even greater advancements:

- Pixel Pitch Miniaturisation: The roadmap leads to even finer pitches below 0.4mm, enabling true 8K resolutions on manageable screen sizes and opening doors for new applications in broadcast and design.

- Power Efficiency Gains: Ongoing innovations in chip design and driving electronics will continue to lower energy consumption, further reducing the total cost of ownership.

- Enhanced Durability: Future iterations will likely incorporate even more resilient materials and self-diagnostic capabilities to predict and prevent failures.

- Smarter Integration: Expect to see deeper integration with AI for automated colour calibration and brightness adjustments, ensuring perfect performance in any environment.

Making Your Investment Count: A Buyer’s Guide to MIP LED Displays

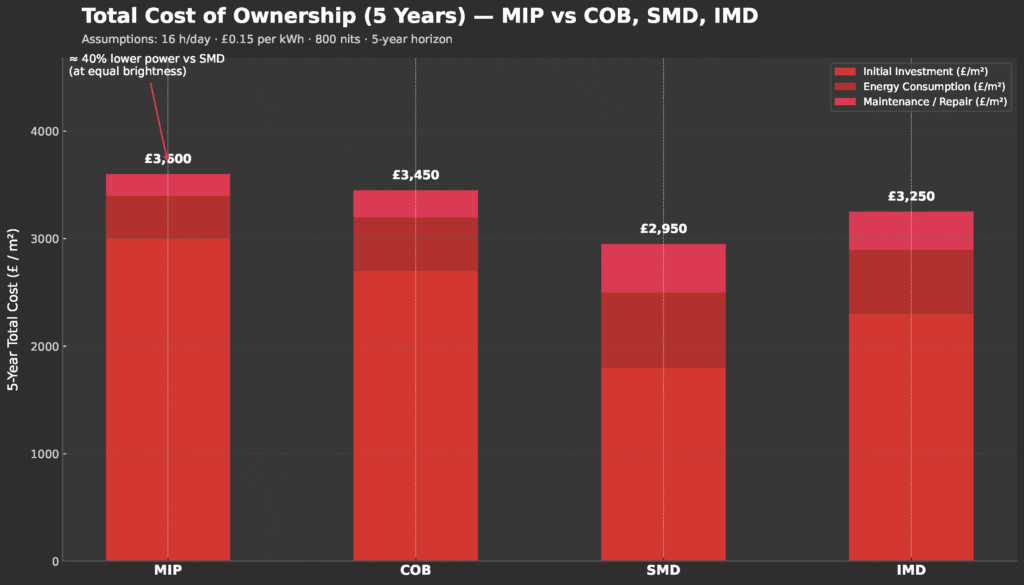

Choosing MIP is an investment in future-proof performance. Its core advantages in durability, efficiency, and serviceability lead to a demonstrably lower Total Cost of Ownership (TCO) compared to technologies that may have a lower initial price but higher long-term operational and maintenance expenses.

When evaluating a potential MIP display, consider these key criteria:

- For Technical Buyers: Focus on the TCO. Ask for data on power consumption at typical brightness levels, Mean Time Between Failures (MTBF) statistics, and the specifics of the on-site repair process and warranty.

- For Creatives: Prioritise visual fidelity. Request demonstrations and look closely at colour gamut (especially coverage of Rec. 2020 or DCI-P3), performance with high-speed video, and off-axis colour consistency.

- For Systems Integrators: Scrutinise the integration process. Confirm compatibility with your preferred control systems, assess the physical mounting requirements, and discuss the availability of technical support and training for your team.

The emergence of MIP technology marks a pivotal moment for the LED industry. It’s a pragmatic solution that delivers the next-generation performance you need with the real-world reliability and cost-effectiveness you demand.

Navigating this landscape requires a partner with deep technical expertise. If you’re ready to explore how our comprehensive LED display solutions can bring your vision to life, our team is here to help you make a confident, informed decision.

Frequently Asked Questions (FAQ) About MIP Displays

Is MIP the same as MicroLED?

Not exactly. MicroLED refers to the microscopic Light Emitting Diode itself. MIP (Micro LED-in-Package) is the method of packaging these MicroLEDs before assembling them into a larger display. MIP is a key enabling technology that makes building large-format MicroLED displays practical and cost-effective.

Is MIP more expensive than COB or SMD?

While the initial purchase price can vary by manufacturer and pixel pitch, MIP is often more cost-effective than COB for fine-pitch applications due to its higher manufacturing yields and use of existing SMT equipment. Its lower energy and maintenance costs result in a significantly lower Total Cost of Ownership over the display’s lifespan compared to both SMD and COB.

What is the ideal use case for MIP displays?

MIP excels in any application that demands a combination of fine pixel pitch, high brightness, extreme durability, and long-term reliability. It is quickly becoming the preferred choice for virtual production studios, premium retail environments, modern control rooms, and high-impact outdoor LED screens.

How does MIP handle heat dissipation?

MIP’s design offers excellent thermal performance. The individual packaging and the materials used help conduct heat away from the LED chip more efficiently than in densely packed COB arrays. This leads to greater stability, longer component life, and sustained brightness levels without risk of overheating.