LED displays are built to last up to an impressive 100,000 hours, but achieving this lifespan depends heavily on how well you maintain them and the environment they operate in. Exposure to factors like dust, moisture, and extreme temperatures can silently wear down your display, leading to reduced performance or even permanent damage. For example, high humidity can corrode internal components, while improper storage conditions outside the ideal range of -40℃ to 60℃ can weaken the system over time.

The good news? A little consistent care goes a long way. Simple practices like regular cleaning, keeping the display active periodically, and routine inspections can help you avoid major problems down the line. By understanding how to protect your screen and control its environment, you can ensure it delivers vivid visuals and reliable performance for years to come.

In this article, we’ll walk you through practical tips and expert insights to make your LED display stay as impressive as the day it was installed!

Why is LED Display Maintenance Important?

Maintaining an LED display is crucial not just for its longevity but also for its performance quality. Regular maintenance ensures consistent brightness and color fidelity, which are vital for the aesthetic and functional quality of the displays. Without routine upkeep, LED displays are susceptible to premature burnout and other malfunctions due to the operational stress from heat, dust, and environmental conditions.

Humidity and dust, for instance, can severely disrupt or corrode the circuit boards, leading to significant maintenance challenges. Data from industry competitors indicate that LED displays that remain idle for extended periods, particularly in moist environments, require a gradual reintroduction to full operational brightness, often needing several hours at reduced brightness to avoid damage.

Neglecting regular maintenance not only leads to higher repair costs and reduced lifespan of the display but also poses potential safety hazards. By adhering to consistent maintenance practices, such as preventing dust buildup, controlling moisture, tightening connectors, and verifying power grounding, significant damages and the associated high costs can be averted. Additionally, maintaining the display under recommended environmental conditions (e.g., humidity control and avoiding direct sunlight) helps preserve the LED components’ quality and functionality.

The life expectancy of high-quality LED chips may reach up to 50,000 hours under controlled conditions; however, this can be substantially reduced by negligence.

What are the Common Issues with LED Displays?

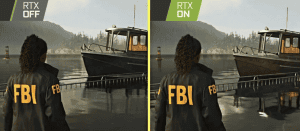

LED displays, acclaimed for their vibrant visuals and efficiency, often face several technical challenges that can degrade their performance and reduce their operational lifespan. One prevalent issue is the appearance of dead or stuck pixels, which show up as black or constantly illuminated spots on the screen, significantly diminishing the quality of the display.

Moisture infiltration presents a serious threat as it can lead to corrosion and electrical shorts, undermining the integrity and safety of the display. Accumulated dust also poses a risk by impeding proper heat dissipation, which can result in short circuits and damage to the display’s internal components.

Overheating is another common concern, as it can damage diodes, driver ICs, and power supplies, especially when the display’s cooling mechanisms, like fans and vents, become blocked. Power fluctuations are equally harmful, causing instability or sudden shutdowns that disrupt the display’s functionality. Additionally, vibrations or thermal expansion can loosen data or power cables, leading to flickering or a complete loss of signal.

Software issues, such as outdated firmware, can cause color misalignment or irregular refresh rates, further affecting the display’s effectiveness. Another long-term concern is image retention, where prolonged display of static images without proper calibration leads to uneven diode aging.

How to Maintain a LED Display?

Proper maintenance of an LED display involves a combination of visual inspections and systematic procedures. Regular visual checks help identify early signs of wear such as dead pixels or discolorations. Systematic maintenance includes cleaning, firmware updates, and regular power checks to ensure all components function as expected.

Ensuring stable voltage and grounding is essential to prevent electrical issues that can damage the display. It’s also advisable to avoid prolonged display of all-white or all-primary-color images at full brightness to prevent pixel wear. If the display is not regularly used, it should be powered on at least once a month to keep all electronic components in good working order.

Connector maintenance is also key; tightening connectors periodically can prevent arcing or intermittent connections that disrupt the display’s functionality. Additionally, it’s important to ensure that all cooling mechanisms, such as fans and vents, remain unblocked to facilitate effective heat dissipation and prevent overheating.

Environmental considerations are also vital. Displays stored or unused in high humidity conditions should be powered up gradually at low brightness to remove moisture and prevent condensation. For displays inactive for more than a week, extending the preheating period to around 12 hours is recommended.

The tools and equipment necessary for maintaining an LED display typically include microfiber cloths for cleaning, small brushes, vacuum or compressed air cans for removing dust, spare modules, and multi-meters for checking electrical continuity.

Cleaning and Dust Removal

To ensure the optimal performance and longevity of LED displays, regular cleaning is essential. Begin by powering off the display and disconnecting it from all power sources to ensure safety during the cleaning process. Removing surface dust can be effectively done using a gentle brush, compressed air applied from a safe distance, or a vacuum with a soft nozzle attachment. This initial step helps prevent any abrasive particles from scratching the display during more in-depth cleaning.

For more stubborn grime or smudges, it is advisable to use a solution of isopropyl alcohol diluted with water. Apply this solution to a microfiber cloth rather than directly onto the LED surface to avoid excess moisture that can damage the electronics. Carefully wipe the surface with gentle, circular motions; applying excessive force or rubbing vigorously can harm the LED bulbs or modules.

Key tools and equipment for this process include microfiber cloths that prevent scratching, antistatic brushes, compressed air cans for precision in removing particles, and vacuums equipped with soft brushes. It is important to avoid using harsh chemicals, direct streams of water, or excessive physical pressure during the cleaning process to maintain the integrity and functionality of the LED display.

Safe Handling and Placement

The display should be installed in a stable, protected location where it is shielded from accidental impacts, which could cause physical damage to the sensitive components. Additionally, ensuring that the display is situated away from high humidity areas (greater than 60%), exposure to rodents, or heavy dust is essential to avoid environmental damage.

If the display is located in a rodent-prone area, implementing safe placement strategies such as rodenticides or protective enclosures is recommended to prevent rodents from damaging the wiring or other components. Moreover, adhering to the recommended operating temperature range, typically between -40℃ to 60℃ for storage, is vital to prevent stress on the LEDs caused by extreme temperatures.

For installations, using the appropriate brackets, mounting frames, and ensuring that temperature and humidity sensors are in place can help monitor and maintain the environment around the display. Protective housings are particularly important for outdoor setups to shield the display from weather-related damage.

Power Management

Effective power management starts with ensuring a stable power supply voltage and proper grounding to prevent any electrical irregularities that could damage the display. Before turning on the LED display, make sure to power up the control computer first; this sequence helps avoid potential power spikes that could occur if the display were powered off abruptly.

To mitigate the risk of power surges, avoid frequently turning the display on and off within short intervals. Instead, maintain a steady usage pattern and consider dimming the screen or powering it down during off-peak hours to minimize heat stress on the LEDs. This practice not only extends the life of the LEDs but also conserves energy.

For installations in areas susceptible to power fluctuations or lightning storms, using Uninterruptible Power Supplies (UPS), surge protectors, and voltage stabilizers is advisable. Additionally, a power meter can be instrumental in monitoring voltage consistency, ensuring the display operates within safe electrical parameters.

Software and Firmware Maintenance

Regularly check the manufacturer’s website or the official documentation for any available updates that might enhance the display’s functionality or address security vulnerabilities. Before applying any updates, it is crucial to back up the current settings to avoid data loss.

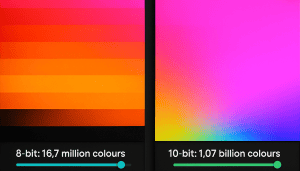

Updating the display’s control system can resolve potential bugs, enhance color accuracy, and improve refresh rates, contributing to a better visual experience. Regular calibration of display settings, such as brightness and color temperature, is necessary to maintain uniformity across panels, ensuring consistent image quality.

Necessary tools and equipment for effective firmware management include a reliable internet connection for downloading updates, a computer equipped with LED control software, and adequate backup storage for existing settings. Additionally, calibration devices are recommended to standardize brightness and color settings across the display modules.

It’s advisable to schedule software updates every 3–6 months or follow the manufacturer’s recommended guidelines. Integrating software update tasks into the overall maintenance schedule ensures that the display remains up-to-date and minimizes the risk of operational disruptions. Always note any changes in display performance post-update and be prepared to roll back if the updates result in unforeseen issues.

Routine Inspections

By scheduling regular checks—either monthly or quarterly based on how intensively the display is used—you can detect and mitigate potential issues before they escalate. During these inspections, focus on examining the panels, power supplies, and all connections thoroughly. It’s essential to look for signs of wear such as loose screws or connectors, damaged cables, and any indications of rust on the enclosure or support frame.

Also, monitor for abnormal heat buildup or issues with cooling fans, which could signify deeper problems. Pay close attention to the environmental conditions surrounding the display. Ensure that no moisture or condensation has accumulated, particularly during rainy or humid periods, as this can lead to severe damage over time.

Environmental Control

Maintaining the optimal environment for an LED display is crucial to its longevity and performance. Continuously monitor the temperature and humidity levels where the display is installed. In regions prone to high humidity or fluctuating temperatures, using dehumidifiers or climate-controlled systems can prevent moisture accumulation and temperature extremes that might damage the display.

For outdoor displays, ensure that all enclosures are IP65-rated or better to effectively ward off rain and dust. Regular inspections should include checks for any potential water infiltration points, and any accumulation of water should be addressed immediately by powering off the system and thoroughly drying the affected areas.

Display Optimization

Optimizing your LED display involves careful calibration of brightness and color settings according to ambient lighting conditions. At night or in dim environments, it’s beneficial to reduce brightness to conserve energy and reduce wear on the diodes. Implementing partial brightness modes can further prevent premature diode wear. Additionally, scheduling software can automate brightness adjustments based on the time of day, which enhances efficiency and reduces manual intervention. For precise adjustments, using control software equipped with cue features, color calibration tools, and light meters ensures that the display’s brightness matches ambient light levels without being unnecessarily high, which is crucial for maintaining the display’s quality and longevity.

Operational Tips

Regularly powering on the LED display, even when not in daily use, helps maintain its functionality. It’s advisable to activate the display at least once a week for a few hours to prevent the components from degrading. To avoid image retention or burn-in, refrain from displaying static or bright solid colors for extended periods. Including rest periods of at least two hours a day, if the display operates continuously, allows the LEDs to cool down and reset. Utilizing automatic timers or scheduling systems can effectively manage operational hours, ensuring the display runs only when necessary. Monitoring software is also beneficial for tracking usage hours, brightness settings, and overall operation cycles, which aids in maintaining the display’s optimal performance over time.

Emergency Maintenance

Immediate action is required in emergency situations to protect your LED display. If water enters the display, power should be promptly disconnected to prevent short circuits and further damage. Consulting a professional technician is crucial for assessing the moisture impact and beginning the necessary repairs. In the event of power surges or blackouts, it’s important to check all power lines, circuit breakers, and fuses before restarting the display to prevent additional electrical issues. Should modules fail unexpectedly, shutting down the affected sections can prevent damage from spreading to other parts of the display until repairs are completed. Keeping a list of emergency contacts, surge protection devices, and having spare modules and power supplies on hand, along with protective gear for safe handling, equips you to quickly and effectively address issues and minimize damage, ensuring the durability and consistent performance of your LED display.

Documentation and Tracking

Maintaining an LED display to its optimal performance level requires meticulous documentation and tracking. Keeping a maintenance log is essential, not just for recording each inspection, but also for detailing repairs conducted and parts replaced. This record helps in tracking operating hours, brightness settings, and noting any environmental anomalies that might affect the display, such as storms or heatwaves.

It’s equally important to maintain an up-to-date record of firmware and software versions along with a history of updates. Such diligent documentation ensures any changes in the display’s performance can be quickly addressed and traced back to specific updates or alterations in environmental conditions.

For managing these records efficiently, spreadsheet software or dedicated maintenance-management systems prove invaluable. Utilizing cloud-based databases or shared folders can also enhance accessibility, ensuring that the maintenance history is available to all relevant team members, no matter their location.

What are the Different LED Display Maintenance Types?

There are primarily two types of maintenance strategies: front maintenance and rear maintenance. Each type is suited to different environments and accessibility needs, impacting how effectively you can manage and service the display.

What Is Front Maintenance?

Front maintenance of LED displays is particularly advantageous in scenarios where space is constrained. This method involves accessing and servicing LED modules directly from the front, which is a common requirement for displays installed flush against a wall or in tightly enclosed spaces. The primary benefit of front maintenance is its convenience, especially in indoor environments where sleek, integrated designs are preferred.

Front maintenance allows for faster module replacement, saving significant time and reducing downtime in critical display applications. This approach is facilitated by magnetic or snap-in panels that can be easily removed to access the underlying LEDs. Such a method is especially useful for smaller pitch indoor LED displays, where minimal disruption is a need. The ease of access without needing to move the entire structure makes front maintenance a preferred choice in many urban installations.

What Is Rear Maintenance?

Conversely, rear maintenance is typically utilized in settings where there is ample space behind the display. This traditional form of maintenance is common with large outdoor billboards and stadium screens, where it is possible to access the rear of the display cabinet. Rear maintenance allows for a more robust construction and easier management of wiring and electrical components, as all serviceable parts are accessible from the back.

This method supports heavier and more secure cabinet designs, which are beneficial in exposed or high-traffic environments. Additionally, rear maintenance facilitates easier heat management and structural integrity over time. It is ideal for permanent installations where space is not an issue, allowing for comprehensive maintenance activities without the need to disrupt the display’s front appearance or operation.

Front vs. Rear Maintenance: Which Should You Choose?

Choosing between front and rear maintenance for your LED display hinges on several factors that affect both the installation and ongoing care of the display. Here’s a concise comparison to help guide your decision:

Comparison Table:

| Feature | Front Maintenance | Rear Maintenance |

| Space Requirements | Ideal for limited spaces; no need for rear access. | Requires open access from behind, suited for larger, spacious installations. |

| Installation Complexity | Higher initial cost due to complex front access mechanisms; simplifies later repairs. | Less complex to install; maintenance access may be cumbersome. |

| Outdoor vs. Indoor | Typically used for indoor displays where space is at a premium. | Commonly used for large outdoor displays like billboards and stadium screens. |

| Frequency of Access | Better for high-traffic areas where frequent maintenance is necessary. | Suitable for locations where the display can be easily accessed from behind. |

What are the Different Types of LED Displays and What are their Maintenance Needs?

LED displays vary in type and application, each demanding specific maintenance strategies to ensure longevity and performance. Indoor LED displays are generally used in environments where the control of ambient conditions is feasible. They typically have lower ingress protection (IP) ratings, and thus, keeping them dust-free and operating at moderate brightness is crucial to prevent overheating and ensure a long service life.

Outdoor LED displays, on the other hand, face harsher environmental conditions. They require enclosures with higher IP ratings, such as IP65, to fend off dust, moisture, and the deleterious effects of UV exposure. These displays need robust power management solutions to handle the greater demands of outdoor operation and should be inspected more frequently to prevent issues such as short circuits or overheating, which can stem from environmental wear and tear.

Transparent LED displays offer a unique aesthetic by allowing light to pass through, making maintenance focused on preserving transparency essential. This means regular cleaning of both sides of the display to maintain clarity and prevent dirt or moisture accumulation that could obscure the view or damage the display.

Flexible or bendable LED displays present their own set of challenges. Their maintenance primarily involves careful handling to avoid damaging the flexible circuit boards. These displays are suited for special installations where traditional flat or rigid screens might not suffice.

Indoor LED Displays

Indoor LED displays thrive in controlled environments. Their maintenance is largely focused on combating dust accumulation that can interfere with both the display’s cooling systems and image clarity. Due to their typically tighter pixel pitches, these displays require gentle cleaning techniques to avoid damaging the LEDs. Whether the display is accessed from the front or the rear for service often depends on the installation’s design constraints.

For venues like indoor arenas or conference halls, ensuring a stable power supply is crucial. This might involve using an uninterruptible power source (UPS) to protect against power surges and maintain consistent operation. Regular inspections should include checking cable connections and clearing out any dust that gathers around ventilation areas to prevent overheating.

Outdoor LED Displays

Outdoor LED displays are engineered to endure extreme weather conditions, including rain, snow, strong sunlight, and wind, making them a staple for outdoor advertising and large-scale public events. These displays typically come with a minimum IP65 rating, ensuring they remain impervious to dust and moisture ingress. The enclosures of these displays feature sealed seams and protective gaskets to further prevent water penetration, crucial for maintaining functionality in varied weather conditions.

High-brightness modules are utilized to ensure visibility even in direct sunlight, but this can lead to increased heat generation within the units. To counteract this, robust cooling solutions are necessary to dissipate heat effectively and maintain stable operation. Maintenance for outdoor displays includes frequent scheduled cleanings—often bi-annually or more often in areas with high levels of dust, pollen, and other airborne pollutants.

Additionally, it’s essential to check the lightning protection systems, such as rods and grounding wires, to ensure they are fully operational, especially in regions prone to thunderstorms. The structural integrity of support frames and fasteners must also be regularly inspected to ensure they can withstand local wind loads and thermal expansion without compromising the display’s stability or safety.

Transparent LED Displays

Transparent LED displays offer a unique visual experience, ideal for storefronts or modern architectural designs, where they blend digital messaging with see-through properties. The maintenance of these displays focuses heavily on preserving the clarity of the glass or acrylic panels they are mounted on. Regular cleaning is essential to maintain transparency and prevent visual obstructions caused by fingerprints, dust, and smudges. Unlike standard LED displays, transparent units require cleaning solutions that are mild and free from harsh chemicals to avoid clouding the transparent surfaces.

Maintenance routines also include careful management of the display’s internal environment to prevent condensation, which can cloud the glass and interfere with the display’s visual output. The routing of cables needs to be managed discreetly to maintain the aesthetic integrity of the installation, ensuring that the see-through effect is not compromised by visible wires or clutter.

In terms of structural considerations, transparent LED displays often feature thinner, more delicate modules that demand gentle handling during both installation and routine maintenance. This care extends to the electronic components, where ensuring a low-humidity environment can prevent moisture-related damage and prolong the display’s operational lifespan.

Flexible/Bendable LED Displays

Flexible or bendable LED displays represent a significant innovation in display technology, allowing for creative configurations that can curve around surfaces and structures. These displays use modules that can bend without breaking, making them ideal for creating immersive environments and unique visual presentations. However, their maintenance needs are distinct due to their unique construction.

Maintenance of these displays focuses on preventing excessive bending or twisting that could exceed the recommended radius of curvature, which could permanently damage the flexible circuit boards. It is crucial to handle these displays with extreme care during installation and regular maintenance checks to ensure that the bending has not affected the integrity of the display.

Dust and moisture management is also critical for maintaining the longevity and performance of flexible LED displays. They require gentle cleaning methods that do not apply strong pressure, which could misalign the delicate components. Furthermore, ensuring that the mounting frame or structure adequately supports the curved shape is vital. An improper installation can lead to stress fractures in the circuit boards over time.

During periodic maintenance checks, it is important to confirm that no module has been dislodged due to repeated adjustments or environmental factors. Cable strain, especially around curved areas, should be monitored to prevent disconnections or damage. Given the specialized nature of these displays, manufacturer-specific repair procedures and guidelines should be closely followed to ensure proper maintenance and handling.

What are the Environmental Factors that Affect LED Display Maintenance?

Environmental factors play a significant role in the performance and longevity of LED displays. Pollution, including dust and industrial pollutants, can accumulate on LED modules, causing brightness reduction and corrosion of circuit boards. Outdoor installations are particularly vulnerable, where wind exposure can shake displays and loosen connectors if mounts and protective cabinets are not secure. High sun exposure introduces another challenge, as UV radiation can degrade LED encapsulation, causing the screen to lose its color quality over time.

Temperature extremes, whether high or low, also strain power supplies and increase the risk of condensation on electronic components. For example, overly high temperatures may cause overheating, while freezing conditions can affect stable operation. Regular climate monitoring and protective enclosures help mitigate these risks, ensuring the display’s service life and quality remain intact.

Maintenance in Hot Weather

High temperatures pose unique challenges for maintaining LED displays. Efficient heat dissipation is advisable, especially in regions prone to extreme heat. Fans and air-conditioning systems must remain fully operational to prevent overheating, while dust buildup around vents and heat sinks should be regularly removed. Prolonged sun exposure may accelerate heat-related wear, so using sunshades or positioning the display in a shaded area can help.

Monitoring internal cabinet temperatures is essential. If temperatures exceed the recommended limits consistently, cooling mechanisms may need upgrading. Alternatively, adjusting brightness settings can reduce thermal loads, preserving the display effect and the lifespan of LED lamp beads. Operators in extremely hot regions may schedule power-down intervals during peak heat hours to alleviate stress on sensitive components.

Maintenance During Rainy Seasons

Rainy seasons can be challenging for both indoor and outdoor LED displays. For outdoor installations, water infiltration is a significant risk. Ensure all enclosures are sealed with weatherproof gaskets and have effective drainage systems to prevent water buildup inside the cabinet. Verify that input ports and power connectors are covered with protective caps to avoid short circuits. Indoor displays are less exposed, but high humidity levels can still cause condensation and damage circuits over time.

If a leak or water infiltration occurs, immediately disconnect power to prevent further damage. Open the enclosure, dry all components thoroughly, and inspect for corroded circuits or modules before restoring power. Using dehumidifiers in the environment can help mitigate moisture accumulation. Outdoor displays should also undergo more frequent checks of grounding rods and lightning protection equipment during storm-prone months.

Maintenance in Cold Weather

Cold weather introduces unique challenges for LED displays, particularly the risks of condensation and thermal stress. When powering up the display, it’s crucial to warm it gradually to avoid sudden temperature shifts that can create condensation on sensitive electronics. In extremely cold regions, insulating the enclosure or using small heating elements helps maintain stable internal temperatures. This reduces the likelihood of damage to the LED modules and power supply.

Check all cables for brittleness, as low temperatures can make them prone to cracking. Avoid operating the display at full brightness immediately after a cold start. Gradually increasing the brightness reduces stress on components like LED lamp beads and power lines. To maintain stable operation, use moisture-absorbing materials within the cabinet to control humidity levels.

What are the Preventive Maintenance Measures for LED Screens?

Preventive maintenance helps protect your investment and avoid costly repairs. Let’s take a look at some tips to keep your LED screens at optimal performance;

- Conduct thorough inspections twice a year to identify loose screws, rust, cable wear, and ensure stable grounding to prevent electrical issues like short circuits.

- Maintain a consistent cleaning schedule for both indoor and outdoor displays. Dust, combined with moisture, can cause severe damage to LED modules and circuit boards.

- Preheat the screen at 30%–50% brightness for displays inactive for more than three days in humid environments. Extend preheating to 12 hours if the screen has been off for over a week.

- Monitor lightning protection devices and surge protectors. Replace them if they have been triggered or show signs of wear to protect the display from power surges.

- Tighten power and data cable connectors after frequent on/off cycles. Loose connections can result in arcing or “virtual connections,” reducing the reliability of your display.

How Do LED Display Maintenance Practices Vary by Industry?

Maintenance needs vary significantly based on the industry and environment where LED displays are installed. Below are the industry-specific practices for optimal maintenance:

- Entertainment and Events: Displays face high-intensity use for short durations. After each event, clean the screen to remove confetti, stage smoke, or accidental impacts. Inspect modules for signs of physical damage.

- Advertising/Billboards: Outdoor displays need frequent weatherproofing checks, pest control, and brightness calibration. Exposure to temperature and humidity fluctuations demands robust sealing and inspections.

- Sports Arenas: Large video walls require reliable power backup systems to avoid disruptions during games. High usage necessitates frequent checks for dead pixels, uneven brightness, and secure cable connections.

- Corporate/Conference Halls: Indoor displays focus on dust control and stable network connections for seamless operation. Minimal downtime is critical to prevent disruptions during meetings or presentations.

How to Handle LED Display Maintenance During High Usage Periods?

Managing LED display maintenance during high-usage periods is critical to maintaining stable operation and avoiding unexpected failures. Here are some actionable tips:

- Schedule quick inspections during off-peak hours or overnight. This ensures minimal disruption while addressing potential issues such as dust buildup, loose connections, or dead pixels.

- Keep a dedicated spare module kit and essential tools onsite. Immediate access to replacement LED modules and repair tools can significantly reduce downtime during high-demand periods.

- Use remote monitoring software to identify performance anomalies in real-time. Monitoring temperature, humidity, and pixel functionality can help you detect and resolve issues before they escalate.

- Consider partial shutdowns of less-visible sections of the LED display screen if necessary. This approach helps minimize interruptions while allowing maintenance personnel to work on problem areas.

- Inspect zones with high image repetition for accelerated wear. High-contrast or static images can strain specific sections, leading to damage or uneven brightness.

- Perform thorough post-event checks to identify any damage or overheating. Cleaning, tightening connections, and testing LED modules after events can ensure the display is ready for the next usage spike.

What are the Costs Associated with LED Display Maintenance?

Maintaining an LED display involves costs that vary depending on the size, type, and usage of the screen. Here’s a breakdown of typical costs in British pounds (£):

- Spare parts: LED modules (£50–£200 per module), power supplies (£100–£300), and cooling fans (£20–£50) are common replacements. Larger video walls or outdoor displays tend to require higher-cost parts.

- Weatherproofing materials: For outdoor LED displays, gaskets and sealing components cost £50–£100 per panel annually to ensure moisture protection.

- Professional inspections: Routine inspections typically range from £300–£600 per visit, depending on the complexity and location of the LED display screen.

DIY Maintenance vs. Professional Services

- DIY Maintenance: Reduces costs but requires technical skills and tools. For example, cleaning tools (like a vacuum cleaner or microfiber cloth) cost £20–£50, while diagnostic software can range from £100–£300.

- Professional Services: Quicker resolutions by manufacturer-trained technicians, with fees averaging £500–£1,000 annually for service contracts. Long-term agreements often reduce per-visit costs.

How Long Does a LED Display Last When Properly Maintained?

A well-maintained LED display typically lasts 50,000 to 100,000 hours, equivalent to 5–10 years of continuous operation. This lifespan can be divided into:

- Economic lifespan: The point where operational costs outweigh the display’s utility, often 7–8 years for most commercial applications.

- Technical lifespan: The period before major component failures, such as LED lamp beads or power supplies.

- Service lifespan: Varies depending on maintenance practices, with regular care ensuring a stable operation and vivid display effect throughout its life.

Are There Legal or Safety Standards for Maintaining LED Displays?

In the UK, maintaining LED displays, especially large outdoor installations, requires compliance with safety and industry standards. Key regulations include:

- Electrical safety standards: Ensuring proper grounding and avoiding short circuits is vital under the UK’s Electrical Equipment (Safety) Regulations 2016.

- Building codes: Displays must meet structural requirements to withstand wind loads and prevent hazards in public spaces. This is particularly crucial for video walls in areas like sports arenas or urban billboards.

- Fire safety regulations: Insulated cables and fire-resistant materials may be required, particularly for indoor installations.

Compliance Tips

- Keep documentation of compliance with local electrical codes and inspections.

- Frequently inspect grounding systems and lightning protection devices to ensure safety.

- Update permits or certifications after relocating displays or making major modifications.

What are the Latest Trends in LED Display Maintenance?

Recent technologies and innovative practices are reshaping how LED screens are maintained, ensuring optimal performance and longevity.

- Remote Monitoring and Diagnostics: Cloud-based systems allow real-time tracking of LED displays, alerting operators to issues such as temperature spikes, power failures, or module malfunctions. This technology minimizes downtime by enabling faster responses to potential problems.

- Automatic Brightness Control: Ambient light sensors adjust the brightness of the LED screen based on surrounding light conditions. This reduces power consumption, extends the service life of the LED modules, and enhances the overall display effect.

- Improved Protective Coatings: Advanced nanocoatings, like the protective resin coverings engineered by Dynamo LED Displays, repel water, dust, and UV rays. These coatings prevent damage from moisture or impact, making the display more resilient in challenging environments.

- Modular Designs: Modern LED panels now feature quick-release systems, enabling easy front or rear access. This modular approach simplifies maintenance, significantly reducing downtime during repairs.

- Predictive Maintenance: Analytics-driven software monitors usage patterns to predict when components like power supplies or LED lamp beads might fail. This proactive strategy helps schedule maintenance before any significant issues arise, ensuring stable operation and consistent visuals.

How to Safeguard Your LED Display from Cybersecurity Risks?

As LED displays integrate with networked systems, safeguarding them from cybersecurity threats is critical. Here are key strategies to protect your LED screen display:

- Secure Login Credentials: Replace default passwords with strong, unique ones and update them regularly.

- Network Segmentation: Keep LED control systems separate from public or unsecured networks to minimize vulnerabilities.

- Firewalls and Intrusion Detection: Install systems to block unauthorized remote access attempts.

- Software Updates: Regularly patch control software to address potential vulnerabilities in older versions.

- Encrypted Content Management: Use HTTPS and role-based access controls to secure content updates for digital signage.

- Audit Logs: Regularly review logs for unusual activity, such as unauthorized login attempts or unapproved content uploads.

When Should You Seek Professional LED Maintenance?

Certain situations necessitate professional maintenance to ensure the optimal performance and longevity of your LED display. Below are key indicators that it’s time to consult an expert:

- Persistent pixel failures: Widespread or recurrent issues compromise the display effect and require advanced diagnostics to address underlying problems.

- Faulty power supplies: Symptoms such as random reboots, flickering, or uneven brightness often point to power source malfunctions that demand specialized repair.

- Software or firmware errors: Complex control system problems or firmware glitches may exceed the scope of routine troubleshooting and benefit from professional intervention.

- Water damage: If water or moisture infiltrates the modules, cabinets, or wiring, prompt expert attention is essential to prevent short circuits or corrosion.

- Physical damage: Cracked panels, bent frames, or damaged components often need professional tools and expertise for proper restoration.

Dynamo LED Display Maintenance

Dynamo Displays is a global leader in LED display solutions, combining innovative technology with unparalleled support services. Their expert technicians handle every stage, from installation to ongoing maintenance:

- Professional installation ensures precision with structural assessments, cabling, and system configuration, guaranteeing reliable operation.

- Comprehensive maintenance programs include regular inspections, cleaning, and quick access to spare parts, keeping displays in peak condition even in challenging environments.

- Dedicated customer support and a robust warranty provide peace of mind and protection for your investment.

Conclusion

We know how important it is for your LED display to look great and work flawlessly every time. With proper care, you can keep it running smoothly, showing sharp visuals and reliable performance for years to come. Simple steps like regular inspections, stable power, and timely updates can save you from unexpected repairs and unnecessary expenses.

Sometimes, though, tackling every issue yourself isn’t practical—and that’s where we come in. At Dynamo Displays, we’re here to handle the tricky stuff, from fixing complex problems to giving your display the professional attention it deserves. Think of your LED screen as an investment; when you take care of it, it pays you back with a longer lifespan, better picture quality, and peace of mind.

Your display is more than just a screen—it’s a way to connect with your audience. Whether it’s showcasing ads, running events, or powering digital signage, a little planning goes a long way. Let’s work together to create a care plan tailored to your display’s unique needs, so it’s always ready to make the impact you want. You’ve made the investment—now let’s protect it, together.