LED displays have earned their reputation for being a reliable and long-lasting solution in countless settings, from vibrant outdoor advertising to high-performance indoor installations. Their durability and efficiency make them a go-to choice, but like any technology, their lifespan isn’t guaranteed without the right care and attention. Whether you’re a business investing in digital signage or a homeowner adding a sleek display to your space, understanding what affects their longevity is key.

When we know what impacts an LED display’s performance—be it environmental conditions, maintenance habits, or power management—it empowers us to make smarter decisions. From choosing the right display to working with reputable manufacturers, these small yet important choices can make a big difference in how well your display performs over time.

In this article, we’ll discuss the key factors that influence the lifespan of LED displays, sharing practical insights to help you get the most out of your investment while ensuring it performs at its best for years to come.

What are the Different LED Display Lifespan Types?

When discussing LED displays, ‘lifespan’ can refer to several aspects, each with significant implications for users and suppliers alike. These include the economic, technical, service, and average lifespan, each defining a specific aspect of the display’s longevity and utility.

Economic Lifespan

The economic lifespan of an LED display is the period during which it delivers the best return on investment (ROI). This is not merely about how long the display lasts before it stops working but rather how long it remains cost-effective. Typically, an LED display can achieve an economic lifespan of up to 10 years, depending on usage intensity and maintenance quality. During this time, the display should operate efficiently without requiring excessive repairs or energy costs, making it a financially viable technology choice for a wide range of applications.

Technical Lifespan

The technical lifespan of an LED display is the period during which it remains at the forefront of technology before newer innovations render it less competitive. Typically, this lifespan lasts approximately 5 to 7 years, depending on the pace of technological advancements in display technology. During this time, an LED display continues to meet industry standards for quality and efficiency without needing significant upgrades or replacements.

Service Lifespan

The service lifespan of an LED display refers to the duration it can operate effectively before succumbing to wear and tear or damage from external conditions. For most high-quality LED displays, this period ranges from 10 to 12 years. This lifespan can be extended with proper maintenance, including regular cleanings and timely repairs, which help prevent common issues such as overheating and component degradation.

Average Lifespan

On average, the lifespan of an LED display is about 100,000 hours, equating to roughly 6-10 years of use. This estimate varies based on the intensity of usage and environmental factors. For instance, displays used outdoors or in high-duty cycles may have shorter lifespans due to harsher operating conditions. Conversely, displays used sparingly in controlled environments may exceed the average lifespan, continuing to function well beyond a decade.

What Is the Average Lifespan of an LED Display?

LED displays are celebrated for their durability and longevity, with a typical lifespan ranging between 50,000 to 100,000 hours, translating to about 5-10 years under normal operational conditions. This impressive lifespan estimation is not indicative of a total failure at the end of this period but rather marks when the LED diodes begin to degrade to half of their original brightness.

During their lifespan, LED components do not degrade uniformly; other components within the display may fail earlier than the LEDs themselves, thus impacting the overall functional lifespan of the unit. For instance, power supplies, cooling fans, and other electronic components may require replacement or maintenance well before the LED elements dim to their half-life brightness.

Furthermore, the operational habits of an LED display greatly affect its longevity. Continuous operation—24 hours a day, 7 days a week—can significantly reduce a display’s lifespan to approximately 5-7 years. Conversely, operating the display for only about 12 hours a day could extend its life beyond 10 years. Understanding these factors is crucial for maximizing the lifespan of LED displays, allowing users to plan effectively for maintenance and replacement, thereby ensuring continuous and efficient use.

Incorporating considerations for energy consumption, component quality, and environmental conditions also plays a critical role in prolonging the effective service life of LED displays. Users are encouraged to adhere to recommended operational practices, engage in routine maintenance, and select high-quality displays from reputable manufacturers to truly leverage the longevity of LED technology.

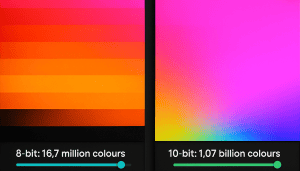

How Does LED Display Lifespan Compare to Other Technologies?

LED displays are renowned for their longevity, often outlasting other display technologies on the market. Here’s a comparative look at the lifespan of LED displays alongside other popular technologies:

- LCD Screens: Typically, LCD screens last about 40,000 to 60,000 hours, or roughly 4.5 to 7 years, depending on usage and maintenance. LCDs use liquid crystal display technology, which, while effective, does not match LED’s longevity due to the nature of the liquid crystals and the backlighting systems used.

- OLED Displays: OLED, or organic light-emitting diode technology, offers a sharper contrast and a wider viewing angle than LCDs. However, OLED displays usually have a shorter lifespan, averaging about 10,000 hours at full brightness. When operated at 25% brightness, they can last up to 40,000 hours, extending their usability to about 1-4.5 years.

- QLED Displays: QLED, standing for quantum dot LED, incorporates quantum dots to enhance performance and longevity. These displays can last approximately 60,000 to 100,000 hours, or about 7-10 years, closely mirroring the upper limits of LED lifespan.

- MicroLED Displays: MicroLED technology, which uses microscopic LEDs to create individual pixels, offers an impressive lifespan of up to 100,000 hours or about 11 years. This makes MicroLED one of the most durable display technologies, suitable for intensive use in high-end displays.

- Plasma Displays: Once a popular choice for large-screen TVs, plasma displays have a lifespan comparable to high-end LEDs and MicroLEDs, generally around 100,000 hours or 11 years. However, the production of plasma displays has largely been discontinued due to the efficiency and cost-effectiveness of newer technologies.

- Reflective LCD Displays: These are less common but are known for their use in environments with variable lighting conditions, lasting more than 60,000 hours or over 7 years. Reflective LCDs don’t rely on backlighting, which significantly reduces their power consumption and extends their operational life.

Display Technology Lifespan Comparison Table

| Technology | Typical Lifespan (Hours) | Equivalent Years (Approx.) |

| LED Displays | 50,000 – 100,000 | 5.7 – 11.4 years |

| LCD Screens | 40,000 – 60,000 | 4.5 – 7 years |

| OLED Displays | 10,000 – 40,000 | 1 – 4.5 years |

| QLED Displays | 60,000 – 100,000 | 7 – 11.4 years |

| MicroLED Displays | 100,000 | Up to 11.4 years |

| Plasma Displays | 100,000 | Up to 11.4 years |

| Reflective LCD Displays | 60,000 and above | 7 years and more |

Why Understanding LED Lifespan Is Important for Consumers and Businesses

Understanding the lifespan of LED displays is crucial for consumers and businesses alike, as it directly impacts investment calculations and return on investment (ROI). Knowing the operational duration of an LED display helps in forecasting maintenance costs and scheduling replacements, which are essential for budgeting and financial planning.

A longer lifespan not only ensures that the initial investment yields a better value over time but also reduces the frequency of replacements, which can be costly and disruptive. For businesses, particularly those that rely on continuous digital signage, the durability of an LED display can significantly affect operational efficiency and marketing effectiveness.

Furthermore, comprehending the lifespan characteristics of different LED displays aids in making informed decisions regarding the most suitable technology for specific applications. Whether for outdoor advertising, indoor information boards, or sophisticated broadcast displays, each usage scenario demands a display technology that aligns with its operational demands and environmental conditions.

What is the Lifespan of Different LED Display Types?

LED displays vary widely in their lifespan, influenced by their design, usage, and environmental exposure. Each type of LED display offers distinct advantages and challenges, making it important to select one that best fits the intended environment and usage to maximize its lifespan and effectiveness.

Indoor LED Displays

Typically, indoor LED displays enjoy a longer lifespan, often exceeding 100,000 hours. These displays are protected from harsh environmental factors like direct sunlight, rain, and extreme temperatures, which can degrade components more rapidly. The controlled indoor environment also means that these displays can operate at lower brightness levels, which conservatively uses their diodes and other electronic components, further extending their service life.

Outdoor LED Displays

Outdoor displays typically endure harsher conditions, which can reduce their lifespan. Exposure to extreme weather, varying temperatures, and high brightness requirements necessary for visibility in sunlight are all factors that can shorten the lifespan of an outdoor LED display. Generally, these displays have a lifespan of around 50,000 to 100,000 hours, but this can be less in particularly severe environments.

SMD (Surface-Mounted Diode) LED Displays

SMD technology allows for more precise control and higher display resolution. Commonly used in both outdoor and indoor settings, SMD LED displays are known for their robustness and longevity, typically ranging from 80,000 to 120,000 hours. Their design allows for better heat dissipation, which plays a crucial role in extending their lifespan.

DIP (Dual In-Line Package) LED Displays

DIP technology is often used for outdoor applications that require high brightness. These LEDs are encased in dual in-line packages, which protect them against environmental factors. The lifespan of DIP LED displays generally matches that of high-quality SMD displays, but they excel in environments requiring high visibility, lasting approximately 100,000 hours.

MicroLED Displays

A newer advancement in LED technology, MicroLEDs offer exceptional longevity due to their efficient light-emitting capabilities and superior heat management. These displays are expected to last over 100,000 hours while providing better color contrast and energy efficiency, making them a promising option for future display needs.

What Factors Influence the Lifespan of an LED Display?

Several key factors impact the lifespan of an LED display, crucial for users who rely on this technology for effective communication and display solutions. Understanding these factors ensures optimal utilization and maintenance, extending the operational life of LED displays.

Temperature and Heat Management

Temperature plays a pivotal role in the performance and lifespan of an LED display. High temperatures can accelerate the degradation of LED components, reducing the display’s lifespan. Effective heat management through proper ventilation and heat dissipation technologies is essential to maintaining optimal operating temperatures and preventing overheating. Conversely, while extreme cold might prolong component life by reducing overheating risks, it can also make certain materials brittle, leading to potential failures in other aspects of the display.

Humidity and Moisture

LED displays exposed to high humidity or direct moisture are at risk of condensation and water ingress, which can cause short circuits and corrosion. To combat these risks, protective measures such as waterproof casings, dehumidifiers, and conformal coatings are used to shield sensitive components. Ensuring that LED displays are installed in well-ventilated areas and protected from direct exposure to the elements helps in preserving their functionality and extending their service life. These precautions are particularly important for outdoor LED displays or installations in humid environments, where moisture can be a persistent threat.

Dust and Dirt

Dust and dirt can significantly impact the performance of LED displays. Accumulated particles block ventilation, leading to overheating of internal components like circuit boards and power supplies. This results in increased energy consumption and reduced longevity. Furthermore, dust absorbs moisture from the air, causing corrosion in delicate parts, such as diodes and control boards.

To mitigate these issues, clean the display panel regularly with appropriate tools and use protective coverings to minimize exposure to dust. Installing displays in areas with controlled environments or proper ventilation can also extend their service life.

Corrosive Environments (e.g., Salty Air in Coastal Areas)

LED displays installed in coastal areas face additional challenges due to salty air. Salt can corrode metallic components, such as connectors and circuit boards, compromising the overall functionality and reducing the display’s lifespan. Corrosion also leads to performance degradation in brightness and image quality.

To prevent such damage, use airtight sealing and protective coatings on LED screens. Selecting display solutions specifically designed for corrosive environments, such as IP-rated outdoor LED products, can further protect against salt and moisture. Regular inspections and cleaning of affected components are also necessary to maintain optimal performance.

Vibration and Mechanical Stress

Vibrations during transport or installation can cause physical damage to an LED display. Loose components, misaligned circuit boards, and weakened solder points are common outcomes of mechanical stress. Over time, these issues lead to failures in the display technology.

Handle displays carefully during transportation and use anti-vibration mounts during installation. Ensure proper alignment and secure mounting of all components to minimize stress. Consulting professionals for installation can help avoid unnecessary damage and enhance the overall reliability of your display.

Power Supply Quality

The quality of the power supply plays a crucial role in extending the lifespan of an LED display. Power fluctuations and voltage surges can damage sensitive components, such as diodes, control boards, and circuit boards. These issues often reduce the display’s longevity and lead to frequent repairs.

To mitigate risks, it’s essential to use high-quality power supplies along with surge suppressors and voltage regulators. These devices protect against electrical irregularities, ensuring the display panel operates efficiently under stable conditions. Investing in reliable power management solutions is critical for maximizing the lifespan and minimizing disruptions.

Why Use a Surge Suppressor and Voltage Regulator?

Surge suppressors and voltage regulators offer vital protection for LED displays. Surge suppressors safeguard against short bursts of high voltage caused by power surges, such as those from lightning strikes or unstable electrical grids. Voltage regulators, on the other hand, maintain consistent power by compensating for prolonged fluctuations in voltage levels.

While surge suppressors prevent immediate damage, voltage regulators help maintain long-term stability in power usage, reducing stress on components. Using both tools together ensures that your LED screen operates under optimal conditions, ultimately extending its service life and preserving its performance.

Daily Usage Patterns

How you use an LED display daily impacts its overall lifespan. Displays running continuously for 24/7 operations often experience increased heat buildup, which accelerates wear and tear. Over time, this reduces brightness levels and shortens the lifespan of key components, such as LEDs and power supplies.

To optimize performance, it’s recommended to limit continuous operation to 12-16 hours per day whenever possible. This reduces heat dissipation challenges and prevents premature degradation.

Content Displayed

The type of content shown on an LED screen significantly impacts its lifespan. Static images tend to wear out certain LEDs faster, especially when paired with high brightness levels. Brighter colors, particularly white, require more power and generate excessive heat, accelerating degradation. Conversely, using darker colors and adjusting brightness to appropriate levels can reduce power consumption and improve heat dissipation, prolonging the lifespan of the display.

Optimal settings not only ensure a longer lifespan but also improve energy efficiency, which is critical for applications like advertising or video walls.

Quality of Components and Manufacturing

The quality of components, such as LED chips, cabinet materials, and circuit boards, directly affects the longevity of an LED display. High-grade materials resist wear better, offer superior heat dissipation, and maintain brightness levels longer. Poor-quality components, on the other hand, are more likely to fail prematurely, leading to costly repairs or replacements.

Strict quality control during manufacturing is essential. Standardized production processes ensure consistency, while reliable LED display manufacturers emphasize durability and performance.

Influence of Manufacturing Techniques

The manufacturing process plays a crucial role in the durability and fatigue resistance of an LED display. Techniques such as proper storage of components, precise welding, and applying three-proofing (moisture-proof, dust-proof, anti-corrosion) significantly enhance resilience. Features like waterproofing and airtight sealing are especially important for outdoor LED displays exposed to harsh conditions.

Installation Practices

Proper installation is critical to the service life of an LED display. Professional installation by experts like Dynamo, a leader in LED display installations, ensures that all aspects—from site surveys to system configuration—are handled with precision. Dynamo’s technicians follow industry standards to position displays correctly, secure them firmly, and manage ventilation and cabling efficiently.

Incorrect angles can create hot spots, leading to uneven heat dissipation. Poorly managed cabling increases the risk of electrical damage, while insufficient ventilation can trap heat, reducing the lifespan of the components.

Environmental Factors

External environmental conditions also play a major role in an LED display’s longevity. Factors such as temperature fluctuations, humidity, and exposure to pollutants can accelerate wear. Displays placed in extreme environments, like areas with heavy rainfall or intense sunlight, require additional protection. Choosing outdoor LED displays with waterproofing and UV-resistant coatings can significantly mitigate environmental damage and improve performance.

High Altitude

At high altitudes, reduced air pressure affects heat dissipation in LED displays. Lower pressure means less effective cooling, which can lead to overheating and component degradation. Displays designed with advanced cooling systems and ventilation features are essential in these conditions to maintain stable performance and extend their service life.

Corrosive Gases

Environments with saline air, such as coastal areas, expose displays to corrosion. Salt particles can damage sensitive components like diodes and circuit boards. To improve reliability, opt for displays with airtight sealing, anti-corrosion coatings, and robust housing. Regular cleaning and maintenance also help prevent salt accumulation, ensuring consistent performance over time.

How to Measure and Monitor LED Display Performance and its Relationship to Lifespan

Modern LED display solutions often include software to track real-time performance metrics. Advanced systems monitor power consumption, internal temperatures, and operational hours to provide alerts on irregularities. Integrating these tools helps identify issues early, extending the service life of the display.

Also, measuring and monitoring the performance of an LED display is critical to maintaining its lifespan and ensuring optimal functionality. Over time, components degrade, and early detection of issues can prevent costly repairs or replacements.

Some of the issues you can avoid with regular monitoring includes;

- Brightness Decay: Regularly check for reduced brightness levels compared to the original specifications. Gradual brightness loss indicates aging LEDs or heat-related degradation. Tools like luminance meters can measure this effectively.

- Dead Pixels: Inspect the screen for non-functioning or discolored pixels. Dead or stuck pixels can disrupt visual quality and signal potential hardware problems.

- Color Consistency: Evaluate uniformity across the display. Variations in color suggest wear in specific modules or power irregularities affecting the diodes.

How Can You Extend the Lifespan of an LED Display?

Proper usage and maintenance can significantly reduce wear, ensuring your investment lasts longer while maintaining optimal performance. Below are practical strategies you can implement to maximize longevity:

- Clean the display regularly: Use non-abrasive materials to gently remove dust and debris from the screen surface and vents.

- Avoid direct contact with bare hands: Fingerprints can leave oils that may damage the screen over time.

- Schedule routine inspections: Regular checks help detect minor issues, like loose connections or dirt accumulation, before they escalate.

- Protect from direct sunlight and harsh conditions: Prolonged exposure to intense sunlight or adverse environments can degrade performance.

- Ensure proper ventilation and temperature control: Adequate airflow prevents overheating and improves heat dissipation.

- Use surge suppressors and voltage regulators: These protect the display from voltage surges and fluctuations, reducing the risk of electrical damage.

- Power on and off correctly: Follow manufacturer guidelines for safe operation and shutdown to avoid unnecessary strain on components.

- Keep firmware and software updated: Updates often include optimizations that enhance performance and durability.

- Avoid abrasive cleaning liquids: Harsh chemicals can degrade the screen’s protective layers or discolor the surface.

What are Common Mistakes That Reduce LED Display Lifespan?

Despite best efforts, certain mistakes can inadvertently reduce the lifespan of LED displays. Being mindful of these errors is essential to avoid costly repairs or replacements:

- Poor installation practices: Improper angles, insecure mounting, or substandard cabling can strain components and reduce reliability.

- Using the display in unsuitable environments: Excessive heat, high humidity, and dusty surroundings can lead to corrosion and overheating.

- Neglecting regular maintenance: Skipping cleaning schedules allows dirt and dust to accumulate, blocking vents and causing overheating.

- Using improper cleaning agents: Harsh or abrasive substances can damage the screen surface or compromise its protective coatings.

- Operating at maximum brightness constantly: This accelerates wear on LEDs, shortens their lifespan, and increases power consumption.

- Inadequate ventilation: Without proper airflow, displays are prone to overheating, which accelerates internal component degradation.

- Ignoring power supply quality: Voltage variations and inconsistent power can damage the circuitry, requiring costly repairs.

- Overloading display components: Running the display beyond its rated capacity puts undue stress on control boards and diodes.

What Are the Signs Your LED Display Needs Replacement?

LED displays have a limited lifespan, and recognizing when they require replacement is essential to avoid disruptions. Below are key indicators that your display may need to be replaced:

- Brightness decay: If the screen’s brightness fades significantly, making content hard to see even at maximum settings, it may be time for a new display.

- Dead or stuck pixels: An increasing number of non-functional or permanently lit pixels can disrupt viewing quality and indicate aging components.

- Color inconsistencies: Uneven color reproduction across the screen often signals issues with LEDs or internal components.

- Frequent technical failures: Recurrent malfunctions, such as control board errors or power issues, can suggest that the display is nearing the end of its service life.

- Overheating: Persistent overheating, despite proper ventilation, may indicate damaged cooling mechanisms or internal wear.

- Outdated technology: Displays that no longer meet industry standards or your specific requirements should be replaced with advanced models.

- Physical damage: Cracks, dents, or structural compromises to the display panel or housing are strong indicators of replacement needs.

Conclusion

Taking care of your LED display is about more than just maintenance—it’s about protecting the investment you’ve made and getting the most out of it. When we choose high-quality displays from trusted manufacturers, we’re already taking the first step toward long-lasting performance. From there, it’s up to us to keep things running smoothly with simple habits like cleaning regularly, ensuring proper ventilation, and keeping an eye on the power supply.

Every bit of effort you put into understanding how environmental factors and usage patterns affect your display pays off. By addressing issues early and staying proactive, you not only extend the lifespan of your screen but also avoid unnecessary costs and downtime.

The goal is to ensure your LED display delivers reliable performance and an exceptional viewing experience for years to come. It’s about smart care today for lasting results tomorrow.

Frequently Asked Questions

Can LED Displays Work 24/7 Without Damage?

Yes, LED displays can operate 24/7, but continuous use accelerates wear, reducing the lifespan. Prolonged operation generates heat, which stresses internal components. To maximize service life, you should schedule downtime during off-peak hours or lower brightness settings when full intensity isn’t necessary. These practices help manage heat dissipation and extend the lifespan of the LED screen.

Do LED Displays Fade Over Time?

Yes, LED displays experience brightness decay over time due to usage and environmental factors. Constant high-brightness settings, exposure to heat, and prolonged operation can speed up this fading process. Regular maintenance and optimized brightness settings can help slow the rate of decay and keep the display performing effectively.

Which Lasts Longer, LED or LCD?

LED displays generally last longer than LCD screens. LEDs have a lifespan of up to 100,000 hours, while LCDs typically last between 40,000 and 60,000 hours. This extended lifespan makes LED technology a better long-term investment for displays requiring high durability and energy efficiency.

How Does Operating Temperature Affect LED Lifespan?

Operating temperature significantly impacts LED lifespan. Higher temperatures accelerate degradation of components, shortening the service life. Proper ventilation and maintaining a stable environment within the recommended range can minimize thermal stress and ensure optimal performance.

Is It Normal for Some LEDs to Fail Before Others?

Yes, it is normal for some LEDs to fail earlier due to manufacturing variances or environmental stress. Over time, individual diodes may degrade or malfunction. Routine maintenance and timely replacement of faulty components help maintain overall display quality and prevent widespread failures.